Warehouse and AI: The Future of Inventory Management and Smart Logistics

How are Warehouse and AI Technologies Transforming Inventory Management?

In today’s fast-paced supply chain environment, warehouse and AI technologies are revolutionizing the way businesses manage inventory. The integration of artificial intelligence into warehouse operations enables smarter, faster, and more accurate inventory control, replacing outdated manual methods.

From Manual Tracking to AI-Powered Intelligence

Traditionally, inventory management relied heavily on spreadsheets, barcode scanning, and human oversight—practices that are prone to error and inefficiency. With the introduction of artificial intelligence warehouse systems, businesses now leverage AI to automate stock monitoring, reduce human error, and optimize replenishment schedules.

AI-driven inventory management systems continuously learn from data, enabling real-time updates, intelligent forecasting, and proactive decision-making. This allows warehouse managers to anticipate shortages, reduce overstock, and ensure that demand is met without excess.

Key Technologies: Sensors, Robotics, and Machine Learning

The transformation is powered by a combination of cutting-edge technologies. IoT-enabled sensors track product movement and environmental conditions in real-time. Robotics automates picking, packing, and sorting tasks, significantly speeding up operations. Machine learning models analyse sales data, seasonal trends, and customer behaviour to forecast demand more accurately than traditional methods.

These systems are integrated into warehouse management software (WMS), allowing for seamless coordination between digital planning and physical execution.

Real-Time Tracking and Predictive Forecasting

Real-time tracking is a cornerstone of AI-enhanced inventory management. It gives businesses visibility into stock levels, location accuracy, and shipment timelines. Combined with predictive analytics, warehouses can proactively adjust inventory levels based on demand trends, promotions, or external disruptions.

In conclusion, the fusion of warehouse and AI technologies is setting a new standard in inventory management—one that is efficient, data-driven, and responsive to change.

What Does an Artificial Intelligence Warehouse Look Like Today?

In the evolving landscape of logistics, warehouse and AI technologies have combined to create the concept of the artificial intelligence warehouse—a highly automated, smart facility designed to optimize every aspect of storage, retrieval, and distribution.

Defining the Artificial Intelligence Warehouse

An artificial intelligence warehouse integrates advanced AI systems with robotics, sensors, and data analytics to automate and streamline operations. Unlike traditional warehouses that rely heavily on manual labour and basic automation, these AI-powered facilities use real-time data and intelligent machines to make autonomous decisions, increasing accuracy and efficiency.

Examples of Automation in AI Warehouses

Modern AI warehouses feature a variety of innovative technologies:

- Smart shelves equipped with sensors that detect stock levels instantly and communicate with inventory management systems.

- Autonomous forklifts that navigate warehouse floors safely and efficiently, transporting goods without human intervention.

- AI-driven picking systems that use machine vision and robotic arms to identify, select, and package items with high precision and speed.

These technologies reduce errors, speed up order fulfilment, and enable 24/7 operations with minimal human oversight.

Real-World Case Studies

Industry leaders such as Amazon have pioneered the use of AI in their fulfilment centres. Amazon’s use of Kiva robots dramatically speeds up order processing by automating item retrieval and delivery to packing stations.

Similarly, Alibaba has deployed AI-powered warehouses in China that use facial recognition for employee access, smart carts for goods transport, and predictive algorithms to manage inventory and demand forecasting effectively.

Other companies are following suit, demonstrating that the artificial intelligence warehouse is rapidly becoming the new standard in supply chain logistics.

How Do Warehouse and AI Systems Improve Accuracy and Efficiency?

The integration of warehouse and AI systems is transforming traditional inventory management by significantly improving accuracy and operational efficiency. These intelligent technologies help businesses reduce errors, optimize workflows, and maintain seamless supply chain processes.

Reducing Human Error in Stocktaking and Order Fulfilment

Manual stocktaking and order fulfilment are often prone to mistakes due to fatigue, miscommunication, or oversight. AI-powered systems use sensors, RFID tags, and computer vision to automate inventory counts and verify order accuracy. This minimizes human errors such as miskicks or misplaced items, ensuring customers receive the right products on time. Automated quality checks further improve reliability and reduce costly returns.

Optimizing Warehouse Layouts and Routing

AI algorithms analyse vast amounts of warehouse data to design optimal layouts and streamline routes for picking and packing. By calculating the most efficient paths for autonomous robots and human workers, these systems reduce travel time and increase throughput. Dynamic slotting—adjusting item locations based on demand patterns—also enhances space utilization and speed.

Predictive Maintenance and Intelligent Inventory Restocking

AI-driven predictive maintenance monitors equipment health by analysing sensor data to anticipate failures before they occur, reducing downtime and repair costs. Similarly, intelligent inventory restocking leverages machine learning to forecast demand accurately, ensuring stock levels meet customer needs without overstocking. This balance optimizes working capital and enhances customer satisfaction.

In summary, the synergy of these systems empowers businesses to achieve higher accuracy, faster operations, and smarter resource management—critical advantages in today’s competitive logistics environment.

What Role Does AI Play in Smart Logistics Beyond the Warehouse?

Artificial intelligence is no longer confined to the walls of the warehouse. Its impact extends throughout the entire logistics ecosystem, transforming transportation management, last-mile delivery, and supply chain optimization into smarter, more efficient processes.

AI in Transportation Management and Last-Mile Delivery

AI systems analyse massive amounts of data from traffic patterns, weather forecasts, and delivery schedules to optimize route planning and fleet management. This results in reduced fuel costs, faster deliveries, and improved vehicle utilization. Last-mile delivery, often the most complex and expensive segment, benefits significantly from AI-driven route optimization and real-time tracking, ensuring packages arrive promptly and customers remain satisfied.

Integration with IoT and GPS Tracking

AI’s power is amplified when combined with the Internet of Things (IoT) and GPS tracking technologies. Sensors placed on trucks, containers, and packages transmit real-time data that AI algorithms use to monitor shipment status, detect anomalies, and predict delays. This seamless integration provides end-to-end visibility, allowing companies to proactively address potential issues before they escalate.

Real-Time Decision-Making and Risk Management

One of AI’s standout advantages in smart logistics is its ability to make real-time decisions. By continuously analysing data streams, AI can reroute shipments to avoid traffic congestion or severe weather, dynamically adjust delivery schedules, and manage inventory shortages. It also enhances risk management by predicting potential supply chain disruptions and suggesting mitigation strategies.

While these technologies revolutionize inventory handling on-site, AI’s role in logistics beyond the warehouse ensures the entire supply chain operates smoothly, efficiently, and responsively to changing conditions.

What are the Challenges of Implementing Artificial Intelligence in Warehousing?

Implementing warehouse and AI technologies offers transformative benefits, but it also presents significant challenges that organizations must carefully navigate to realize the full potential of AI-powered warehousing.

High Initial Investment and Infrastructure Changes

One of the primary barriers to adopting AI in warehousing is the substantial upfront investment required. Deploying AI-driven robotics, sensors, and data platforms demands a robust technological infrastructure that may require upgrading existing warehouse facilities. This includes installing IoT devices, high-speed connectivity, and compatible warehouse management systems (WMS). For many companies, especially small to medium-sized enterprises, these capital costs can be prohibitive.

Data Quality and Integration Issues

Effective AI depends on high-quality, consistent data. Warehouses often struggle with fragmented data sources, incomplete records, and outdated systems that hinder AI algorithms’ accuracy and effectiveness. Integrating AI with legacy software and ensuring real-time data flow across the supply chain is complex and resource-intensive. Poor data quality can lead to faulty predictions, inventory errors, and operational inefficiencies, undermining trust in AI solutions.

Workforce Adaptation and Upskilling Needs

Another significant challenge lies in workforce adaptation. Employees accustomed to traditional manual processes may resist adopting AI-driven tools due to fear of job loss or unfamiliarity with new technologies. Successful implementation requires comprehensive training and upskilling programs to help staff collaborate with AI systems effectively. Additionally, organizations must manage change carefully to maintain morale and productivity during the transition.

In conclusion, while their integration holds great promise, overcoming challenges related to investment, data management, and workforce readiness is critical for successful AI adoption in modern warehousing.

What are the Benefits of Combining Warehouse and AI in a Digital Supply Chain?

The integration of warehouse and AI technologies plays a pivotal role in advancing digital supply chains, offering numerous benefits that drive efficiency, customer satisfaction, and sustainability.

Increased Productivity and Reduced Operational Costs

By automating repetitive tasks such as inventory tracking, picking, and packing, AI-powered warehouses significantly boost productivity. Robotics and AI-driven systems reduce manual errors and downtime, allowing operations to run smoothly around the clock. This automation not only speeds up workflows but also cuts labour costs and minimizes the need for costly rework, leading to substantial operational savings.

Faster Delivery Times and Improved Customer Satisfaction

AI’s real-time data analysis enables smarter inventory management and demand forecasting, ensuring the right products are stocked and ready to ship. Combined with optimized routing and autonomous handling systems, these innovations accelerate order fulfilment and reduce delays. Faster deliveries increase customer satisfaction and help businesses stay competitive in an age where consumers expect rapid service.

Enhanced Sustainability through Optimized Energy Use and Waste Reduction

Digital supply chains powered by these solutions contribute to sustainability goals by optimizing resource use. AI can monitor energy consumption patterns and adjust equipment operation to minimize waste. Additionally, better demand forecasting reduces overstock and product spoilage, lowering overall waste. These efficiencies help companies reduce their environmental footprint while maintaining profitability.

In summary, the synergy of warehouse automation and artificial intelligence revolutionizes supply chains by improving productivity, speeding delivery, and supporting sustainable practices—key drivers for success in today’s digital economy.

What is the Future Outlook for Artificial Intelligence Warehouse Solutions?

The future of warehousing is closely tied to advancements in warehouse and AI technologies, which continue to evolve and reshape logistics operations worldwide.

Emerging Trends: Warehouse Drones, Generative AI, and AI Twins

One exciting trend is the deployment of warehouse drones for inventory audits, stock monitoring, and even item picking. These drones can quickly scan shelves and hard-to-reach areas, increasing accuracy and efficiency. Another breakthrough is the use of generative AI in logistics planning, which enables dynamic, optimized scheduling and resource allocation based on real-time data inputs. Additionally, the concept of AI twins—digital replicas of physical warehouses—allows companies to simulate and analyse operations virtually, predicting issues and testing improvements before implementing them on the warehouse floor.

AI’s Role in Global Supply Chain Resilience

The COVID-19 pandemic highlighted the vulnerabilities in global supply chains. AI-powered warehouses play a critical role in enhancing supply chain resilience by providing adaptive, data-driven insights. Predictive analytics help anticipate disruptions and optimize inventory buffers, ensuring that supply chains remain agile and responsive to changing market demands.

Automation and Workforce Redefinition

As AI and automation take on more complex tasks within warehouses, workforce roles are evolving. Rather than replacing humans, automation is redefining jobs—shifting workers towards supervisory, analytical, and technical positions. This transformation requires ongoing upskilling and collaboration between humans and intelligent machines to maximize productivity and innovation.

In summary, the integration of these solutions is steering the logistics industry toward a future marked by greater efficiency, resilience, and smarter human-machine partnerships.

Conclusion

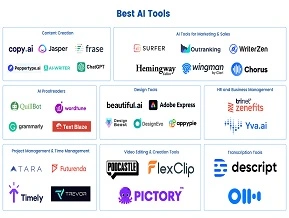

LAI offers specialized courses designed to equip learners with the skills needed for careers involving these technologies in smart logistics. These programs cover essential topics such as automation, data analysis, and AI model deployment, providing practical, hands-on experience through real-world projects. LAI’s curriculum is tailored to prepare students for various roles in logistics and supply chain management, supported by industry-recognized certifications. By learning through LAI, individuals can confidently enter the rapidly growing field of AI-powered logistics and advance their careers in a tech-driven supply chain landscape.