Automation and AI the Perfect Duo for Transforming Manufacturing in 2025

What is the Role of Automation and AI in Manufacturing?

Automation and AI are transforming the manufacturing landscape by streamlining operations, improving efficiency, and enabling smarter decision-making. While automation focuses on performing tasks with minimal human intervention, AI adds intelligence to these processes, allowing systems to learn, adapt, and improve over time.

Defining Automation and AI and Their Individual Roles

Automation refers to the use of machines and technology to perform repetitive tasks, such as assembly line operations, welding, or packaging, without direct human input. AI, or artificial intelligence, complements this by enabling machines to analyze data, recognize patterns, and make decisions. Together, they form a powerful combination that goes beyond basic automation.

How AI Enhances Traditional Automation Systems

AI in automation brings a new level of flexibility and responsiveness to manufacturing systems. Traditional automation operates on fixed programming, which can be rigid and hard to adjust. AI-enhanced systems, however, can adapt in real-time to changing conditions, optimize production schedules, predict equipment failures, and reduce downtime through predictive maintenance. This leads to greater efficiency, quality control, and overall productivity.

Key Technologies Enabling AI in Automation

Several advanced technologies enable the integration of AI in automation. Robotics plays a central role by executing physical tasks with precision. The Internet of Things (IoT) connects machines and sensors, collecting real-time data from the production floor. Machine learning algorithms then analyse this data to detect trends and inform decision-making. These technologies work together to create smart, autonomous manufacturing environments.

The convergence of AI in automation is not just enhancing efficiency—it’s redefining what’s possible in modern manufacturing, driving innovation, competitiveness, and scalability in the industry.

How is AI Revolutionizing Manufacturing Processes Through Automation?

Automation and AI are reshaping modern manufacturing by introducing smart, adaptive systems that enhance efficiency, accuracy, and productivity. When combined, these technologies transform traditional factories into intelligent, self-optimizing production environments.

Predictive Maintenance Powered by AI

One of the most impactful applications of AI in automation is predictive maintenance. By analysing data from machines and sensors, AI can detect early signs of wear or failure. This allows manufacturers to perform maintenance before breakdowns occur, reducing downtime, avoiding costly repairs, and extending equipment lifespan.

Real-Time Quality Control and Defect Detection

AI systems equipped with computer vision and machine learning algorithms enable real-time quality control. These systems can inspect products on the assembly line and detect defects with high precision—far beyond human capability. Immediate detection and correction of errors ensure consistent product quality and minimize waste.

AI-Driven Supply Chain and Inventory Management

AI in automation also streamlines supply chain operations. By forecasting demand, tracking shipments, and managing inventory in real time, AI helps manufacturers optimize logistics and reduce excess stock or shortages. This leads to improved responsiveness, cost savings, and more agile operations.

Intelligent Robotics and Autonomous Production Lines

Advanced robotics powered by AI are capable of performing complex tasks with high accuracy. These intelligent robots learn from their environment and adapt to changes without constant human input. Combined with AI systems, autonomous production lines can make decisions, adjust workflows, and self-correct, enabling round-the-clock manufacturing with minimal supervision.

As the integration of these accelerates, manufacturers are gaining a competitive edge through smarter, faster, and more reliable processes—ushering in a new era of industrial innovation.

What are Sustainability and Environmental Impact of Automation and AI in Manufacturing?

Reducing Waste through AI-Driven Process Optimization

One of the most significant contributions of automation and AI in manufacturing is the ability to reduce material waste. By using machine learning algorithms to analyze production data, manufacturers can detect inefficiencies, minimize defects, and optimize resource usage. These AI-driven insights help ensure that raw materials are used more efficiently, leading to less scrap, fewer reworks, and a more sustainable production process.

Energy Efficiency Improvements with Smart Automation

Smart automation systems are designed to monitor and regulate energy consumption across the production line. Sensors and AI algorithms track real-time usage, allowing machines to power down when idle and optimize power usage during peak operations. This dynamic energy management not only lowers operational costs but also significantly reduces the environmental footprint of manufacturing facilities.

Supporting Circular Economy Initiatives with AI Insights

AI technologies play a critical role in supporting circular economy principles. By tracking product life cycles, AI can help design more recyclable components, predict when parts should be refurbished, and guide end-of-life material recovery strategies. Automation supports the physical processes of sorting and disassembly, making sustainable manufacturing not only possible but scalable.

Balancing Productivity Gains with Environmental Responsibility

While increasing productivity is a primary goal, automation and AI also help manufacturers achieve environmental goals. By balancing output with intelligent resource use and minimal waste, companies can meet sustainability standards and improve their brand reputation. Long-term, these systems support global efforts to create cleaner, greener industrial practices.

Through the integration of these AI and automation, manufacturers are proving that technological advancement and environmental responsibility can go hand in hand.

What are Benefits of Combining Automation and AI in Manufacturing?

Increased Operational Efficiency and Productivity

The integration of automation and AI enables manufacturers to significantly increase operational efficiency. AI-powered systems analyze real-time data to make quick decisions and optimize production schedules, while automated machinery executes tasks with speed and precision. This synergy eliminates bottlenecks, reduces cycle times, and ensures that manufacturing processes operate at peak performance with minimal intervention.

Reduced Downtime and Maintenance Costs

Predictive maintenance is a major advantage of combining automation with AI. AI algorithms monitor equipment health and detect signs of wear or failure before breakdowns occur. This proactive approach reduces unplanned downtime, lowers repair costs, and extends the life of machinery. Automated maintenance alerts and scheduling further streamline upkeep, keeping production lines running smoothly.

Enhanced Product Quality and Consistency

Automation ensures that tasks are performed uniformly, while AI continuously monitors outputs for deviations. Together, they enhance product quality and consistency by detecting defects in real time and adjusting processes instantly. Machine learning models can also recommend process improvements, leading to higher standards and customer satisfaction.

Flexibility to Adapt to Changing Production Demands

Modern markets require agility. Automation and AI allow manufacturers to quickly adjust to shifts in demand, customize products, and scale operations without major disruptions. AI analyses market trends and inventory levels, guiding production strategies, while automation systems swiftly reconfigure to accommodate new designs or volumes. This flexibility supports innovation and responsiveness in a fast-changing business landscape.

By combining the strengths of automation and AI, manufacturers can build smarter, more resilient operations that are ready for the challenges of the future.

What are Challenges in Implementing Automation and AI in Manufacturing?

Integration with Legacy Systems and Infrastructure

One of the most common barriers to implementing AI in manufacturing is the challenge of integrating new technologies with existing legacy systems. Many factories still rely on older machinery and software that were not designed to interface with modern AI solutions. Upgrading or replacing infrastructure can be costly and time-consuming, often requiring custom solutions and careful change management to avoid disrupting ongoing operations.

Workforce Adaptation and Skill Development

The adoption of automation and AI requires a workforce that is ready to work alongside advanced technologies. This shift demands new skill sets, including data literacy, machine operation, and systems analysis. Without adequate training and support, employees may feel threatened or overwhelmed, leading to resistance and slower adoption. Manufacturers must invest in reskilling programs to ensure that workers are equipped to thrive in the evolving workplace.

Data Security and Privacy Concerns

With the rise of connected devices and data-driven operations, protecting sensitive manufacturing data becomes a top priority. AI systems often rely on vast amounts of data, raising concerns about data security and privacy. Unauthorized access, cyberattacks, or internal breaches can compromise intellectual property and disrupt production. Implementing robust cybersecurity measures is essential to secure AI-powered manufacturing environments.

Managing Costs and ROI Expectations

While automation and AI offer long-term benefits, the upfront investment in technology, integration, and training can be substantial. Manufacturers may struggle to justify the costs if short-term ROI is unclear. Setting realistic expectations, planning for phased implementation, and measuring incremental gains are important strategies for managing both financial risk and executive buy-in.

Successfully overcoming these challenges is key to unlocking the full potential of automation and AI in the manufacturing sector.

What are Some Successful Case Studies of Automation and AI Adoption in Manufacturing?

Global Examples of Transformation

Across the globe, leading manufacturers are leveraging automation and AI to modernize their operations, reduce costs, and improve product quality. For instance, Siemens has implemented AI-driven predictive maintenance across its factories, reducing equipment downtime and saving millions in repair costs. In Japan, FANUC uses intelligent robotics and machine learning to monitor and adjust machining operations in real time, resulting in consistent quality and minimized waste.

Meanwhile, Tesla’s gig factories serve as a high-profile example of end-to-end automation. From AI-powered robots assembling batteries to automated logistics systems, Tesla has pushed the boundaries of how fully integrated automation can drive scalability and speed in production.

Lessons Learned and Best Practices

Several best practices have emerged from these successful implementations. One key lesson is the importance of starting small with pilot projects. Many manufacturers begin by automating a single process, such as quality inspection, and then scale up based on results. This phased approach reduces risk and builds internal confidence.

Another critical factor is workforce engagement. Companies like Bosch and GE have invested in continuous learning and reskilling programs to help employees transition into new roles alongside AI technologies. This has fostered a culture of innovation rather than resistance.

Finally, aligning automation strategies with long-term business goals ensures that investments in AI deliver measurable value. Leaders who set clear KPIs and focus on both cost reduction and product improvement are better positioned for success.

These case studies show that when applied thoughtfully, automation and AI can drive transformational change in manufacturing—improving efficiency, fostering innovation, and positioning companies for future growth.

What is the Future Outlook for Automation and AI in Manufacturing by 2025?

Emerging Trends and Innovations on the Horizon

By 2025, automation and AI will be even more deeply embedded in manufacturing environments, driving greater autonomy, efficiency, and responsiveness. One emerging trend is the use of AI-driven digital twins—virtual replicas of physical systems that simulate, predict, and optimize performance in real time. Edge computing will also gain traction, allowing faster data processing at the machine level, reducing latency, and supporting real-time decision-making.

The Role of AI in Enabling Smart Factories and Industry 4.0

AI will be the backbone of smart factories, where systems communicate seamlessly and adapt autonomously. These factories, key to Industry 4.0, will use AI to self-monitor, self-optimize, and even self-repair. From demand forecasting and adaptive production lines to predictive maintenance and intelligent quality control, AI will empower manufacturers to achieve higher levels of precision, agility, and customization.

Robots will evolve into collaborative assistants (cobots), working safely alongside humans while learning and improving from every interaction. Additionally, AI-driven analytics will enhance supply chain visibility and resilience, helping manufacturers anticipate disruptions and respond more effectively.

How Manufacturers Can Prepare and Leverage These Advancements

To thrive in this rapidly advancing landscape, manufacturers must invest in digital transformation today. Key steps include modernizing legacy infrastructure, implementing scalable AI platforms, and upskilling the workforce for AI-integrated roles. Strategic partnerships with tech providers and participation in innovation ecosystems will also be crucial.

By embracing these preparations, manufacturers can unlock new opportunities for growth, sustainability, and global competitiveness in the era of intelligent manufacturing.

Conclusion

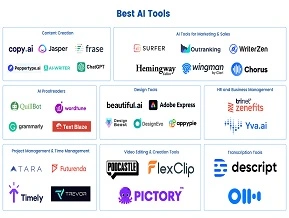

Automation and AI are reshaping the manufacturing industry by driving efficiency, innovation, and long-term competitiveness. From predictive maintenance to intelligent supply chains, their impact is transformative. To stay ahead, manufacturers must prioritize ongoing education and skill development. Investing in AI training not only empowers the workforce but also ensures readiness for future technological shifts. Explore industry-relevant AI courses at LAI to build the knowledge and capabilities needed to lead in the era of smart manufacturing.