Artificial Intelligence Warehouse Solutions from Automation to Predictive Analytics

How is the Artificial Intelligence Warehouse Transforming the Future of Inventory Management?

Artificial intelligence warehouse solutions are reshaping how businesses manage inventory, offering smarter, faster, and more accurate processes. As supply chain demands grow, the integration of advanced AI technologies is helping warehouses become more efficient and responsive.

Automated Inventory Tracking and Real-Time Stock Updates

Modern warehouse systems now leverage AI to automatically track inventory in real time. These systems monitor stock levels continuously, alerting managers about shortages or excesses. This ensures better stock optimization, reduces carrying costs, and improves order fulfilment rates.

AI-Powered Robotics for Picking, Packing, and Sorting

AI-powered robotics are playing a vital role in warehouse automation. These intelligent machines handle repetitive tasks such as picking, packing, and sorting with remarkable speed and precision. By reducing dependence on manual labour, businesses can minimize delays, handle higher volumes, and maintain consistency in operations.

Use of Computer Vision and Sensors

With the help of computer vision and IoT sensors, warehouses can identify products, read barcodes, and track item locations with minimal human input. These technologies work together to monitor goods' movement, enhance security, and streamline warehouse navigation. AI algorithms process data from cameras and sensors to support accurate decision-making in real time.

Improving Accuracy and Reducing Human Error

Manual inventory management often results in errors that lead to stock discrepancies or lost sales. AI reduces these errors by automating data collection, verification, and analysis. This improves the reliability of inventory records and reduces costly mistakes, enhancing overall customer satisfaction.

By embracing the synergy of warehouse and AI innovations, businesses can achieve greater transparency, agility, and efficiency in inventory management. These technologies are not just a trend—they are the future of smarter warehouse operations.

How is the Artificial Intelligence Warehouse Preparing the Workforce for the Future?

Artificial intelligence warehouse systems are rapidly transforming logistics operations, and with this shift comes the need to upskill and reskill the workforce. As automation and AI become central to warehouse environments, investing in employee training is essential to keep operations efficient and workers relevant.

Importance of Upskilling for AI-Integrated Environments

The rise of AI in warehousing is creating new roles that require technical know-how. Employees must be trained to work alongside smart technologies such as AI-powered robots and data-driven inventory systems. Upskilling ensures that workers remain productive and can handle complex tasks that machines cannot fully automate.

Continuous Learning to Adapt to Automation

To thrive in an AI-driven landscape, warehouse workers need to embrace lifelong learning. Continuous training programs focused on automation tools, software systems, and data interpretation equip employees to adapt to evolving technologies. This helps minimize resistance to change and boosts workforce confidence.

Industry-Education Collaboration

Collaboration between logistics companies and educational institutions is key to building a talent pipeline ready for AI integration. By developing specialized courses and certification programs, schools and training centres can prepare students for real-world warehouse and AI environments. Internships and hands-on learning can further bridge the gap between theory and practice.

Promoting Digital Literacy and Technical Skills

Promoting digital literacy among warehouse staff is critical for the successful adoption of AI tools. Training should include basic coding, data analysis, and understanding machine interfaces. These skills help employees interact effectively with AI systems, leading to smoother workflows and fewer errors.

Building a future-ready warehouse and AI workforce requires a strategic focus on education, adaptability, and technical growth. With the right support, employees can not only survive but thrive in the era of AI-powered logistics.

How is Artificial Intelligence Warehouse Automation Streamlining Operations?

Artificial intelligence warehouse automation is revolutionizing logistics by enhancing speed, efficiency, and accuracy in warehouse operations. With the integration of advanced AI technologies, warehouses are becoming smarter, more responsive, and significantly less reliant on manual processes.

Autonomous Guided Vehicles (AGVs) and Drones

AGVs and drones are reshaping material handling in modern warehouses. These autonomous systems transport goods across the facility, reducing the need for forklifts and manual labor. AGVs follow predefined routes or dynamically adjust to real-time data, while drones perform inventory checks and monitor stock levels from above, saving both time and effort.

AI-Driven Workflow Optimization

AI enables intelligent workflow planning and task scheduling. Using machine learning algorithms, systems can predict order volumes, optimize picking routes, and assign tasks based on real-time priorities. This ensures that resources are used efficiently and warehouse throughput is maximized during peak times.

Integration with Warehouse Management Systems (WMS)

The seamless integration of AI with warehouse management systems enhances visibility and control. AI-powered WMS platforms process vast amounts of data to identify patterns, forecast demand, and make data-driven decisions. This helps warehouse managers reduce bottlenecks, manage inventory more accurately, and respond quickly to disruptions.

Benefits in Speed, Cost, and Safety

One of the biggest advantages of automation is the dramatic increase in operational speed. AI systems complete repetitive tasks faster and with fewer errors. Cost savings are achieved through reduced labour, lower overhead, and improved inventory accuracy. Additionally, automation improves workplace safety by reducing the risk of human error and physical strain.

What is Predictive Analytics in Artificial Intelligence Warehouse?

Predictive analytics in intelligence warehouses is transforming how logistics operations forecast, plan, and respond to demand. By leveraging data and machine learning algorithms, warehouses can proactively manage inventory, prevent equipment failures, and improve overall supply chain efficiency.

Forecasting Demand and Optimizing Stock Levels

AI-powered predictive analytics helps warehouses anticipate customer demand based on historical sales, seasonal trends, and market signals. This enables better stock level management—ensuring high-demand items are available while reducing excess inventory. Accurate forecasting reduces waste, saves storage space, and improves customer satisfaction through timely fulfilment.

Predictive Maintenance of Equipment

In artificial intelligence warehouses, predictive maintenance is crucial for avoiding unplanned downtime. AI analyses sensor data from equipment like conveyors, robotics, and forklifts to detect early signs of wear or malfunction. Maintenance can then be scheduled before a breakdown occurs, enhancing equipment lifespan and operational continuity.

Data-Driven Decision Making for Supply Chain Efficiency

With predictive analytics, warehouse managers gain actionable insights from real-time and historical data. These insights support smarter decisions across the supply chain—from choosing the right suppliers to planning transportation routes. This proactive approach leads to faster delivery times, lower costs, and more resilient logistics networks.

Real-World Examples of Predictive Analytics

Major e-commerce and retail companies are already benefiting from predictive analytics in their warehouses. For instance, Amazon uses AI to forecast regional demand and adjust inventory distribution across fulfilment centres. Similarly, logistics firms use predictive tools to optimize delivery schedules and avoid delays caused by traffic or weather disruptions.

By integrating predictive analytics, ai warehouses are not only improving efficiency but also gaining a competitive edge in an increasingly data-driven world.

What are some Benefits of Implementing Warehouse and AI Solutions?

Warehouse and AI solutions are revolutionizing supply chain management by enabling smarter, faster, and more accurate operations. From automation to real-time data insights, these technologies offer significant benefits for businesses aiming to stay competitive in a rapidly evolving logistics landscape.

Enhanced Operational Efficiency and Productivity

Integrating AI into warehouse operations streamlines workflows, automates repetitive tasks, and minimizes delays. AI-driven tools optimize picking routes, prioritize orders, and allocate resources more effectively. This leads to a significant increase in daily throughput, reduced idle time, and better use of both human and technological resources.

Reduction in Operational Costs and Errors

By automating processes such as inventory tracking, sorting, and data entry, warehouses can dramatically reduce human error and associated costs. AI systems maintain high accuracy, reducing losses due to misplaced items or incorrect shipments. Predictive analytics also help in avoiding overstocking and understocking, improving cost control.

Improved Customer Satisfaction Through Faster Fulfilment

With AI-enhanced systems, warehouses can process and ship orders faster, ensuring timely deliveries. Real-time tracking and accurate inventory visibility contribute to better communication and reliability. Customers benefit from quicker response times, fewer delivery errors, and a smoother shopping experience—key factors in building loyalty.

Scalability and Flexibility in Warehouse Management

As demand fluctuates, AI-enabled systems allow warehouses to scale operations up or down without major disruptions. Whether expanding into new markets or handling seasonal peaks, warehouse and AI integration provides the flexibility to adjust resources and processes quickly. This agility is crucial for meeting market demands efficiently.

By embracing warehouse and AI technologies, companies can unlock long-term gains in performance, cost savings, and customer experience—making their supply chains more resilient and future-ready.

What are Challenges and Considerations in Adopting Artificial Intelligence Warehouse Technologies?

Adopting artificial intelligence warehouse technologies offers significant benefits but also comes with challenges that businesses must carefully consider to ensure successful implementation.

High Initial Investment and Integration Complexity

One of the primary hurdles is the substantial upfront cost associated with purchasing AI systems, robotics, and necessary infrastructure. Beyond cost, integrating these technologies with existing warehouse management systems can be complex and time-consuming. Companies need to plan carefully to minimize disruption and ensure smooth interoperability between new AI solutions and legacy systems.

Data Security and Privacy Concerns

As AI technologies rely heavily on data collection and processing, warehouses face increased risks related to data security and privacy. Protecting sensitive business and customer information from cyber threats is essential. Establishing robust cybersecurity protocols and complying with relevant data protection regulations are critical to mitigating these risks.

Training Workforce to Work Alongside AI Systems

Introducing AI requires employees to adapt to new workflows and technologies. Training programs must focus on upskilling staff to operate, monitor, and collaborate with AI-powered tools. Without proper training, resistance to change or misuse of technology could hinder productivity and overall success.

Ensuring Reliability and Handling System Failures

Dependence on AI systems demands high reliability. Unexpected failures or downtime can disrupt warehouse operations, leading to delays and financial losses. It is vital to develop contingency plans, including manual override options and regular system maintenance, to manage risks associated with technology failures.

By addressing these challenges thoughtfully, businesses can maximize the benefits of it while minimizing potential setbacks, paving the way for more efficient and future-ready warehouses.

What is the Future of Artificial Intelligence Warehouse Solutions?

The future of warehousing is being shaped by artificial intelligence warehouse solutions that are increasingly sophisticated, efficient, and sustainable. As technology evolves, warehouses will become smarter ecosystems, integrating AI, robotics, and connected devices to meet growing demands.

Emerging Trends in AI and Robotics

Next-generation AI and robotics are driving innovations such as advanced autonomous guided vehicles (AGVs), robotic arms with enhanced dexterity, and AI-powered drones for inventory management. These technologies improve accuracy, speed, and flexibility, enabling warehouses to handle more complex tasks with minimal human intervention.

Role of IoT and Edge Computing

The Internet of Things (IoT) combined with edge computing is transforming AI warehouses by enabling real-time data processing close to the source. Sensors embedded throughout the warehouse provide continuous monitoring of inventory, equipment health, and environmental conditions. Edge computing reduces latency and bandwidth usage, allowing AI systems to react instantly to changing conditions and optimize operations more effectively.

Increasing Use of AI for Sustainable Operations

Sustainability is becoming a key focus in warehouse management. AI is being utilized to reduce energy consumption, optimize space utilization, and minimize waste. Smart climate control, predictive maintenance, and efficient route planning contribute to greener operations, supporting corporate environmental goals.

Vision for Fully Autonomous Warehouse Ecosystems

Looking ahead, the goal is to create fully autonomous warehouse ecosystems where AI manages everything from inbound logistics to order fulfilment and shipping. These warehouses will seamlessly integrate robotics, AI analytics, and IoT, requiring minimal human oversight and delivering unprecedented levels of productivity and precision.

By embracing these innovations, it will redefine logistics, making warehouses more agile, sustainable, and ready for the future.

Conclusion

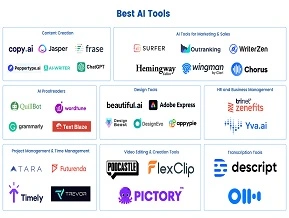

Consequently, it has significantly transformed the logistics landscape by enhancing automation, improving predictive analytics, and increasing operational efficiency. These innovations are helping businesses make smarter decisions, reduce errors, and streamline warehouse processes for better performance. To stay competitive in this evolving field, professionals are encouraged to explore AI-focused courses at LAI, which offer practical insights into AI applications in warehouse environments. As the industry moves toward greater automation and sustainability, embracing these technologies now will equip organizations with the agility and scalability needed for long-term success in warehousing and supply chain management.