Supply Chain and AI Integration: Real-World Examples that Deliver Results

How are Supply Chain and AI Technologies Connected?

The Modern Supply Chain: Definition and Scope

In today’s fast-paced global market, supply chain and AI technologies are becoming increasingly interconnected. A modern supply chain encompasses the entire lifecycle of a product—from raw material sourcing and manufacturing to warehousing, transportation, and final delivery. It also includes demand forecasting, inventory management, and customer service, all of which require real-time decision-making and optimization.

AI Technologies Transforming Supply Chains

Artificial intelligence (AI) is revolutionizing supply chain management through a range of advanced technologies. Machine learning algorithms help forecast demand and detect patterns in purchasing behaviour. Computer vision is used in warehouses for object recognition and quality control. Predictive analytics enables businesses to anticipate delays or disruptions before they occur. Natural language processing (NLP) facilitates smooth communication between systems and humans, such as in automated customer service or order processing. Meanwhile, robotics plays a key role in automating warehouse operations and transportation logistics.

Benefits of AI Integration in the Supply Chain

Integrating AI into supply chain operations offers significant advantages. First, it increases speed by automating repetitive tasks and accelerating data processing. Second, it improves accuracy, reducing human error in forecasting and inventory tracking. Third, it enhances efficiency by optimizing routes, inventory levels, and staffing. Finally, it leads to significant cost reduction by minimizing waste, avoiding stockouts, and streamlining operations.

As businesses face growing demands for faster, more reliable, and more sustainable logistics, AI is becoming an essential tool for innovation and competitiveness. By leveraging AI technologies, supply chains can evolve into intelligent, adaptive systems that respond in real time to market conditions and customer needs.

What is the Real-World Impact of AI in Supply Chain Optimization?

Optimizing Key Areas with AI

The use of AI in supply chain management is reshaping how companies approach critical operations. AI is now widely used to optimize inventory management by analysing sales trends, seasonal demand, and stock levels in real time. In logistics, AI algorithms help determine the most efficient delivery routes, reduce fuel consumption, and improve fleet management. For demand forecasting, machine learning models process vast amounts of data to predict customer needs with high accuracy. In procurement, AI enables smarter supplier selection, risk management, and automated purchasing decisions.

Industry Leaders Using AI for Efficiency

Several global companies are already reaping the benefits of AI-driven supply chains. For instance, Amazon uses AI to power its robotic fulfilment centres, streamline delivery routes, and manage inventory across multiple warehouses. Walmart employs AI for demand forecasting and to optimize shelf stocking. Siemens uses AI in its digital supply chain to reduce downtime and increase flexibility. These companies showcase how AI can lead to smarter and faster decision-making across the supply chain.

Measurable Benefits of AI Integration

The results of integrating AI into supply chain operations are both visible and quantifiable. Companies report reduced lead times thanks to faster data processing and more responsive logistics. Operational costs drop significantly as AI identifies inefficiencies and automates labour-intensive tasks. Additionally, accuracy in inventory levels, demand predictions, and delivery schedules improves, resulting in better customer satisfaction and fewer losses.

As businesses face increasing pressure to deliver faster, reduce waste, and remain competitive, AI proves to be a critical asset. The integration of supply chain systems is not just a trend—it’s a strategic shift toward smarter, more resilient operations.

What are the Emerging Trends Shaping the Future of AI in Supply Chain Innovation?

Next-Gen Technologies Shaping Supply Chains

The future of AI in supply chain innovation is being shaped by cutting-edge technologies like generative AI, digital twins, and autonomous supply chains. Generative AI is being used to simulate complex supply chain scenarios, helping businesses plan for disruptions and test strategies without real-world risks. Digital twins—virtual replicas of physical supply chains—enable real-time monitoring and performance optimization. Meanwhile, autonomous supply chains are emerging, where AI makes decisions and executes tasks with minimal human input, increasing speed and reducing costs.

Real-Time Intelligence with Edge AI

Edge AI is transforming how supply chains operate by enabling real-time data processing at the source—such as warehouses, factories, and vehicles. This significantly reduces latency and allows for faster, more accurate decision-making. For instance, edge AI can detect equipment failures as they happen, adjust inventory automatically, or reroute deliveries based on current traffic conditions. Combined with real-time data analytics, it empowers supply chains to respond proactively rather than reactively.

Control Towers and Risk Management

Another major trend is the rise of AI-powered control towers, which provide a centralized view of the entire supply chain. These platforms leverage AI to monitor operations, flag anomalies, and provide actionable insights. This visibility enhances proactive risk management, enabling companies to anticipate and address disruptions before they impact the bottom line. Whether it’s geopolitical shifts, weather events, or supplier delays, AI helps mitigate risks with agility and precision.

As these technologies continue to evolve, the future of supply chain management looks increasingly autonomous, intelligent, and responsive. Businesses that embrace these innovations will be better equipped to handle complexity, drive efficiency, and gain a competitive edge in a rapidly changing world.

How is AI in Supply Chain Reshaping Industries Worldwide?

Industry Applications Across the Globe

The integration of AI in supply chain operations is transforming industries across continents. In healthcare, AI streamlines the distribution of medical supplies, predicts shortages, and ensures the timely delivery of critical resources. The automotive industry uses AI to optimize parts sourcing, track global shipments, and manage just-in-time production schedules. In retail, AI enhances inventory management, personalizes product recommendations, and supports demand forecasting. Manufacturing benefits from AI-driven automation, predictive maintenance, and supply network optimization.

Managing Global Disruptions with AI

AI has proven vital in navigating global challenges such as pandemics, natural disasters, and geopolitical tensions. During COVID-19, companies used AI to adjust to rapidly shifting consumer demands and disrupted logistics networks. AI-driven models helped reroute shipments, identify new suppliers, and anticipate delays. In times of political instability or trade restrictions, AI assists businesses in analysing risk scenarios and creating contingency plans, helping them adapt quickly without halting operations.

Building Resilient and Adaptive Supply Chains

One of the most significant contributions of AI is its role in creating resilient and adaptive global supply chains. AI enables real-time visibility across all supply chain nodes, allowing companies to detect vulnerabilities and respond swiftly. Machine learning algorithms can predict potential failures, while automated systems adjust operations to minimize impact. This flexibility helps organizations maintain continuity and service quality, even in volatile environments.

As globalization and digital transformation accelerate, the influence of supply chain strategies becomes increasingly critical. By enhancing agility, efficiency, and foresight, AI is not just improving supply chains—it’s reshaping how entire industries operate and compete on the world stage.

What are the Challenges of Integrating AI in Supply Chain Operations?

The Importance of Data Quality and Availability

A major challenge in implementing supply chain operations is ensuring access to high-quality, consistent data. AI systems rely on vast amounts of accurate and timely data to generate insights and make decisions. However, many companies struggle with fragmented data sources, inconsistent formats, and outdated information. Without clean, reliable data, AI algorithms cannot perform effectively, leading to flawed forecasts, misinformed decisions, and reduced trust in automation.

Compatibility with Legacy Systems

Another barrier to successful AI integration is the difficulty of aligning new technologies with existing legacy systems. Many supply chains operate on infrastructure that was not designed to handle modern AI tools. Integrating AI with outdated software or hardware can require costly upgrades, extensive reconfiguration, or even full system replacements. This technical complexity can slow down implementation, create compatibility issues, and hinder scalability across the organization.

Skill Gaps and Organizational Resistance

Deploying AI in the supply chain also requires a skilled workforce capable of managing and interpreting AI tools. However, there is often a skills gap, with few employees trained in data science, machine learning, or AI systems. Additionally, there may be resistance to change among staff who fear job displacement or are uncomfortable adopting new technologies. Overcoming this challenge involves not only upskilling current employees but also fostering a culture that embraces innovation and continuous learning.

While the benefits of supply chain management are significant, these challenges highlight the need for thoughtful planning, investment in training, and strong change management strategies. By addressing these barriers, organizations can unlock the full potential of AI and position themselves for long-term success in a competitive global market.

How Can you Get Started with AI in Supply Chain?

Starting the AI Adoption Journey

For organizations looking to implement supply chain operations, the journey begins with understanding specific business needs and identifying areas with the highest potential for improvement—such as demand forecasting, inventory optimization, or logistics. It’s essential to start small by selecting a manageable use case that delivers clear value. This focused approach helps build confidence, demonstrate ROI, and create momentum for broader adoption.

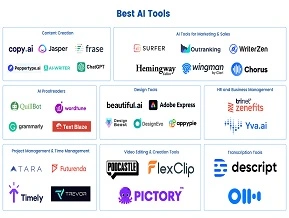

Top AI Tools and Platforms for Supply Chain Management

Several leading platforms are helping businesses harness the power of AI in their supply chains. SAP Integrated Business Planning (SAP IBP) uses machine learning to improve forecasting accuracy and simulate supply chain scenarios. IBM Watson Supply Chain offers AI-driven insights to detect, predict, and resolve disruptions in real time. Microsoft Azure AI provides scalable cloud-based services for predictive analytics, intelligent automation, and real-time visibility. Other tools like Oracle SCM Cloud, Amazon Web Services (AWS) AI, and Google Cloud AI also offer robust solutions tailored to supply chain needs.

Training, Pilots, and Implementation Best Practices

A successful AI rollout involves a clear strategy, cross-functional collaboration, and continuous learning. Begin by training staff on AI fundamentals and use cases relevant to supply chain functions. Run pilot projects to test AI capabilities in a controlled environment and gather feedback. During implementation, follow best practices such as setting measurable goals, ensuring data readiness, and choosing the right technology partners. It's also important to align AI initiatives with broader business objectives and build internal support through change management.

By taking a phased, strategic approach, businesses can unlock the benefits of supply chain management—improving efficiency, agility, and resilience in a rapidly evolving global market.

What are the Learning Opportunities to Master AI in Supply Chain?

The Need for Education and Upskilling

As AI in supply chain operations becomes more widespread, the demand for professionals with the right knowledge and skills is growing rapidly. Traditional supply chain roles are evolving, requiring familiarity with data analytics, machine learning, and digital tools. To stay competitive, supply chain professionals must embrace lifelong learning and actively pursue upskilling opportunities. Understanding AI technologies not only enhances job performance but also opens doors to more strategic and high-impact roles within an organization.

Explore Courses on the LAI Platform

The Learn Artificial Intelligence (LAI) platform offers a range of beginner-friendly and advanced courses specifically tailored to AI applications in the supply chain. Learners can explore topics such as machine learning for logistics, AI-driven demand forecasting, predictive analytics, and automation in warehouse management. Courses are designed to be flexible, practical, and industry-relevant, making them ideal for working professionals or career switchers. In addition to technical training, LAI also provides soft skills development, including change management and digital transformation strategies.

Building a Career in AI-Powered Supply Chains

Mastering supply chain management can lead to exciting and future-ready career paths. Roles such as Supply Chain and ai Analyst, Data-Driven Logistics Manager, Predictive Maintenance Specialist, and AI Implementation Consultant are in high demand across industries like retail, manufacturing, healthcare, and tech. Learners can start by building a solid foundation in AI through courses, followed by hands-on projects and certifications that demonstrate their expertise. Networking with professionals and staying updated on industry trends will further support career growth.

By investing in education and gaining practical experience, learners can position themselves at the forefront of a fast-evolving field—driving innovation and efficiency in global supply chain systems.

Conclusion

The integration of supply chain and AI technologies offers a powerful strategic advantage for modern businesses. By leveraging AI for tasks like demand forecasting, inventory optimization, and logistics automation, companies are achieving real-world benefits such as increased efficiency, reduced costs, and greater accuracy. Looking ahead, AI will continue to transform global supply chain networks, making them more intelligent, adaptive, and resilient to disruption. For both professionals and organizations, embracing this shift is essential. With the right education, tools, and commitment to innovation, anyone can help shape the future of supply chain excellence through AI.