SCM Management: 5 Key Strategies to Optimize your Supply Chain in 2025

How can you Embrace AI and Predictive Analytics?

In today’s dynamic supply chain environment, SCM management must evolve to stay competitive. One of the most transformative strategies businesses can adopt is the integration of artificial intelligence (AI) and predictive analytics into their operations. These technologies are revolutionizing how organizations handle forecasting, inventory control, and demand planning.

Enhancing Forecasting and Demand Planning

AI-powered systems analyse large volumes of historical data and real-time market signals to generate accurate demand forecasts. Unlike traditional methods, AI models adapt quickly to market fluctuations, seasonality, and unexpected disruptions. This leads to more informed decision-making and ensures businesses can respond proactively to changes in consumer behaviour.

Smarter Inventory Optimization

Predictive analytics helps companies maintain optimal inventory levels by forecasting demand patterns, minimizing stockouts, and reducing excess inventory. AI tools can recommend restocking schedules, identify slow-moving items, and optimize warehouse space—streamlining operations while cutting costs.

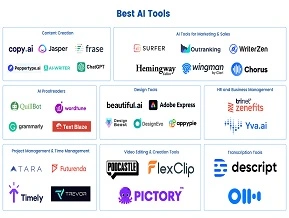

Real-World AI Tools in SCM

Numerous AI-driven tools are making a significant impact on modern supply chains. Platforms like Blue Yonder, Llamasoft (by Coupa), and o9 Solutions use machine learning algorithms for supply chain planning, risk analysis, and performance improvement. These systems integrate seamlessly with existing ERP software, providing actionable insights in real time.

Competitive Edge Through Early Adoption

Companies that embrace AI early often experience a strategic advantage. From faster decision-making to increased customer satisfaction, the benefits are substantial. Early adopters also build internal capabilities, improve data infrastructure, and position themselves as innovators in their industry—making it harder for competitors to catch up. It is a forward-thinking strategy that drives efficiency, resilience, and long-term success in today’s global supply chain landscape.

How Can you Build Resilient and Agile Supply Networks?

The need for robust and flexible supply chains has never been clearer. In the wake of global disruptions such as the COVID-19 pandemic, geopolitical tensions, and climate-related events, companies have realized that traditional, rigid supply networks are no longer sustainable. To thrive in this new era, management SCM must prioritize resilience and agility as core strategic objectives.

Key Lessons from Global Disruptions

Recent years have exposed the vulnerabilities in global supply chains—long lead times, over-dependence on single suppliers, and lack of visibility have led to severe delays and losses. Businesses that lacked contingency plans found it difficult to respond to sudden shocks, highlighting the need for proactive risk management and diversified supplier bases.

Strategies for Building Resilience and Agility

To build resilience, organizations should diversify their supplier networks, invest in nearshoring or reshoring, and create digital supply chain twins to simulate various disruption scenarios. Agility, on the other hand, can be fostered by adopting real-time data analytics, enhancing supply chain visibility, and empowering teams to make faster, decentralized decisions.

Additionally, collaboration across the supply chain ecosystem—from suppliers to logistics providers—is crucial. Strong partnerships improve communication and coordination, enabling a quicker response to unexpected changes in demand or supply.

The Role of Agile Methodologies

Applying agile methodologies to supply chain design brings many benefits. Iterative planning, cross-functional collaboration, and continuous feedback loops allow businesses to adapt quickly to changes. Agile supply chains are not only faster but also more customer-centric, as they can adjust offerings and delivery models based on real-time market needs.

In conclusion, building resilient and agile supply networks is essential for future-proof management SCM. It empowers organizations to minimize risks, respond rapidly to change, and gain a competitive edge in uncertain global markets.

Why Should you Invest in End-to-End Supply Chain Automation?

In the rapidly evolving world of global trade, SCM management must prioritize efficiency, accuracy, and scalability. One of the most effective ways to achieve this is by investing in end-to-end supply chain automation. From procurement to delivery, automation is transforming the supply chain landscape, offering organizations greater control and operational excellence.

Automation Across Key Supply Chain Functions

Automation is being applied across multiple areas of the supply chain. In procurement, automated systems can handle supplier selection, purchase orders, and invoice processing with minimal human input. In warehousing, robotics and automated storage and retrieval systems (AS/RS) improve picking accuracy and reduce manual labour. Logistics is also benefiting from automation through route optimization, real-time tracking, and autonomous delivery vehicles.

Boosting Efficiency and Reducing Costs

One of the most compelling benefits of automation is the improvement in operational speed and accuracy. Automated systems process tasks faster than manual methods, drastically reducing delays and human errors. This leads to improved order accuracy, reduced returns, and faster delivery times. Over time, automation helps lower labour costs, minimize waste, and increase profitability.

The Role of AI and Robotics

AI and robotics play a central role in modern supply chain automation. AI algorithms can forecast demand, monitor supply risks, and optimize inventory levels in real time. Meanwhile, robotics handles repetitive tasks such as sorting, packaging, and transporting goods within warehouses. The combination of AI and robotics ensures that operations are not only faster but also smarter and more adaptive. Organizations that embrace automation gain a significant edge in speed, efficiency, and resilience, setting themselves up for long-term success in an increasingly complex global market.

How Can you Integrate Sustainable and Ethical Practices?

Sustainability and ethics are no longer optional—they are vital to the success of modern strategies. As global markets evolve, consumers, regulators, and investors increasingly expect companies to operate responsibly. Integrating sustainable and ethical practices into the supply chain helps organizations build trust, reduce environmental impact, and enhance long-term value.

The Rising Importance of Sustainability

Sustainability is now a strategic priority for companies across industries. From reducing greenhouse gas emissions to minimizing waste, sustainable supply chains play a key role in protecting the planet and securing a future-ready business. Ethical sourcing, fair labour practices, and transparency are equally important in ensuring companies meet global compliance standards and social expectations.

Leveraging AI for Ethical and Environmental Oversight

Artificial intelligence is a powerful tool in advancing sustainable supply chain practices. AI-powered platforms can monitor supplier activities, track emissions across the supply chain, and detect potential violations of ethical standards. These systems provide real-time insights that help businesses proactively manage risks, ensure compliance, and improve performance. For instance, AI can analyse transportation routes to minimize fuel consumption or verify that suppliers meet labour and environmental regulations.

Aligning with Consumer Expectations

Today’s consumers are more informed and socially conscious than ever. They want to buy from brands that prioritize sustainability and ethical integrity. Companies that fail to align with these values risk damaging their reputation and losing market share. Conversely, businesses that are transparent and committed to ethical practices enjoy increased brand loyalty and customer trust.

In conclusion, embedding sustainability and ethics into it not only meets stakeholder expectations but also builds a resilient, responsible, and future-proof supply chain. It’s a strategy that delivers both competitive advantage and a positive global impact.

How Can you Improve Collaboration Through Cloud and IoT Technologies?

In the digital age, effective SCM management depends on real-time communication, data sharing, and seamless coordination across the supply chain. Cloud computing and Internet of Things (IoT) technologies are key enablers of this transformation, allowing businesses to collaborate more efficiently and make data-driven decisions with greater accuracy.

Real-Time Data Flow and Connectivity

Cloud platforms provide centralized access to critical supply chain data, enabling teams, partners, and suppliers to collaborate in real time, regardless of location. When paired with IoT sensors, companies can capture and transmit data directly from physical assets such as containers, vehicles, or warehouse equipment. This continuous data flow ensures timely updates and allows for quick responses to changing conditions.

Practical Applications in Supply Chain Operations

Cloud and IoT technologies are being widely adopted for inventory tracking, logistics management, and vendor coordination. Smart sensors monitor inventory levels, temperature, and location, helping reduce spoilage and stockouts. In logistics, GPS-enabled devices and connected fleets allow real-time tracking of shipments, enhancing delivery accuracy and reducing delays. Vendors can access shared platforms to synchronize production schedules, ensuring smoother operations and fewer disruptions.

Enhancing Supply Chain Visibility

One of the biggest challenges in supply chain management is limited visibility. Cloud and IoT solutions offer a transparent, end-to-end view of the entire supply chain. Stakeholders can monitor performance metrics, detect inefficiencies, and anticipate potential risks with advanced analytics dashboards. This visibility helps improve forecasting, streamline communication, and build trust across the network. Businesses that invest in these tools are better equipped to respond to market changes, optimize operations, and maintain a competitive edge.

How Can you Leverage Data-Driven Decision Making?

Today, data is one of the most valuable assets in supply chain management. Leveraging data-driven decision making allows organizations to uncover hidden trends, make accurate forecasts, and respond swiftly to operational challenges.

Turning Data into Actionable Insights

Modern supply chains generate vast amounts of data every day—from inventory levels and supplier performance to transportation metrics and customer demand. By using advanced analytics, interactive dashboards, and machine learning algorithms, businesses can turn raw data into meaningful insights. These insights help identify inefficiencies, predict disruptions, and support smarter strategic decisions.

The Role of Real-Time KPIs and Operational Data

Real-time access to key performance indicators (KPIs) is critical for supply chain responsiveness. Dashboards that display up-to-date metrics such as order fulfilment rates, lead times, and delivery performance enable supply chain managers to act quickly and make informed adjustments. Operational data also helps improve forecasting accuracy and optimize everything from procurement to last-mile delivery.

Data as a Strategic Asset

Treating data as a strategic asset empowers companies to become more proactive and competitive. By continuously analysing supply chain performance, businesses can anticipate market changes, reduce risks, and enhance overall efficiency. Moreover, data transparency across the supply chain builds stronger relationships with partners and promotes accountability.

It transforms supply chain operations from reactive to predictive, allowing organizations to improve performance, increase agility, and deliver greater value. As technology continues to evolve, companies that invest in data analytics will be better positioned for long-term success.

How Can you Upskill Talent for the AI-Driven Supply Chain?

In the era of intelligent automation and digital transformation, the human element of management SCM is more important than ever. As AI, machine learning, and automation reshape supply chain operations, businesses must invest in upskilling their workforce to remain competitive and innovative.

The Human Side of AI in Supply Chain Management

While technology enables faster and more accurate decision-making, human oversight remains essential for strategic thinking, ethical judgment, and collaboration. Supply chain professionals must now work alongside advanced tools, interpreting data, validating AI recommendations, and guiding technology implementation to align with business goals.

Cross-Functional Skills for the Future

To thrive in an AI-driven environment, SCM professionals need a blend of technical and strategic skills. Key areas include data literacy, AI fluency, and change management. Understanding how to read dashboards, interpret predictive analytics, and work with automation tools is no longer optional—it’s critical. Additionally, professionals must be agile and adaptable, able to collaborate across departments like IT, operations, and finance.

Empowering Teams Through Training

Organizations should offer targeted training and certification programs to upskill their workforce. Programs focusing on AI in supply chains, data analysis, and digital logistics can help bridge the knowledge gap. Platforms such as Coursera, edX, and specialized SCM training providers offer flexible learning options for professionals at all levels. By investing in employee development, companies not only improve internal capabilities but also boost morale and retention.

Upskilling ensures that professionals are equipped to harness the full potential of AI and emerging technologies, making the supply chain more agile, innovative, and future-ready.

Conclusion

The future of scm management hinges on integrating the eight key strategies: embracing AI and predictive analytics, building resilient networks, automating end-to-end processes, embedding sustainability, improving collaboration with cloud and IoT, leveraging data-driven decisions, and upskilling talent for AI-driven supply chains. Together, these approaches create a powerful synergy between technology, sustainability, and skilled professionals. For effective management scm, companies must adopt a proactive mindset, continuously innovating to stay competitive in an ever-changing global landscape. The time to act is now to build smarter, more agile, and responsible supply chains.