Beginner’s Guide to Manufacturing and AI: How to Get Started?

What is Manufacturing and How Does Artificial Intelligence Transform it?

Manufacturing and AI are two powerful forces shaping the future of industry worldwide. Manufacturing refers to the process of converting raw materials into finished goods through various methods, machinery, and human labor. It encompasses a wide range of activities, from assembling components to packaging products, serving as the backbone of economies by delivering everything from everyday items to complex machinery.

Artificial Intelligence (AI) is the branch of computer science focused on creating systems capable of performing tasks that typically require human intelligence. These tasks include learning, reasoning, problem-solving, and decision-making. AI technologies involve machine learning, computer vision, robotics, and natural language processing, enabling machines to analyze data, identify patterns, and optimize processes.

The integration of AI into manufacturing operations is truly a game-changer. By embedding AI technologies, companies can achieve unprecedented levels of efficiency, precision, and flexibility. AI-powered systems enhance predictive maintenance by forecasting equipment failures before they happen, reducing downtime and costly repairs. Moreover, AI enables real-time monitoring and quality control, ensuring products meet the highest standards without manual inspection.

The importance of AI in modern manufacturing cannot be overstated. It accelerates production cycles, optimizes supply chains, and facilitates customization at scale. AI-driven automation minimizes human error and operational costs, allowing manufacturers to respond swiftly to market demands and innovate faster. As a result, businesses gain a competitive edge in an increasingly dynamic and digitalized marketplace.

In summary, the fusion of manufacturing expertise with artificial intelligence is transforming traditional production into a smart, agile, and highly efficient system, setting a new standard for industrial excellence.

What are the Key Concepts Behind Understanding Manufacturing and Artificial Intelligence?

The integration of smart technologies is transforming the industrial landscape, making production systems faster, more efficient, and highly adaptive. One of the most significant drivers of this transformation is the combination of manufacturing and artificial intelligence, which enables companies to unlock new levels of productivity and precision.

Types of AI Technologies Used in Manufacturing

Several cutting-edge AI technologies are being applied across the manufacturing sector:

- Machine Learning (ML): ML uses historical and real-time data to identify patterns, optimize production schedules, and improve quality control.

- Computer Vision: This technology is widely used for defect detection, visual inspection, and process monitoring with unmatched speed and accuracy.

- Robotics: AI-driven robots can perform repetitive and complex tasks, such as assembly and packaging, with high efficiency and consistency.

- Internet of Things (IoT): IoT devices gather and transmit data from equipment and sensors, feeding AI systems for better process control and predictive insights.

How AI Integrates with Manufacturing Processes?

AI is embedded at every stage of the manufacturing lifecycle. It connects with existing systems such as ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) to enable intelligent automation and real-time decision-making. From planning and design to production and logistics, AI helps streamline workflows, reduce downtime, and enhance overall efficiency.

Examples of AI Applications in Manufacturing

- Predictive Maintenance: AI detects potential equipment failures before they occur, avoiding unplanned stoppages.

- Smart Inventory Management: AI forecasts demand and adjusts stock levels dynamically.

- Automated Quality Control: AI ensures consistent product quality through real-time inspections.

- Self-Optimizing Production Lines: AI coordinates machines and processes for continuous improvement.

This intelligent integration is reshaping how manufacturers operate, setting a new standard for innovation and operational excellence.

What are the Benefits of Implementing AI in Manufacturing?

The adoption of Artificial Intelligence (AI) in the manufacturing sector is transforming how products are designed, produced, and delivered. By automating complex tasks, predicting issues before they occur, and making data-driven decisions, AI enables manufacturers to achieve higher performance and resilience in today’s competitive landscape. Below are the key benefits of implementing AI in manufacturing.

Improved Efficiency and Productivity

AI systems analyse vast amounts of data to optimize workflows, reduce manual tasks, and minimize errors. Smart automation tools can handle repetitive processes—such as assembly or packaging—at a faster pace and with greater consistency. As a result, production cycles become shorter, resource utilization improves, and human workers can focus on high-value tasks, increasing overall productivity.

Predictive Maintenance and Reduced Downtime

One of the most impactful uses of AI in manufacturing is predictive maintenance. By monitoring machine data in real time, AI can detect early signs of wear and potential failure. This allows maintenance teams to intervene before a breakdown occurs, significantly reducing unplanned downtime and maintenance costs. It also extends equipment life and improves workplace safety.

Quality Control and Defect Detection

AI-powered computer vision systems and machine learning algorithms enhance quality control by identifying defects and inconsistencies at early stages of production. These systems can inspect hundreds of items per minute with exceptional accuracy, ensuring only high-quality products move forward. This not only reduces waste but also boosts customer satisfaction and brand reputation.

Supply Chain Optimization

AI enables smarter supply chain management by forecasting demand, optimizing inventory levels, and identifying potential disruptions. Real-time data analysis helps manufacturers adjust procurement, production, and distribution strategies dynamically, resulting in cost savings, faster deliveries, and improved supplier coordination.

In conclusion, implementing AI in manufacturing drives innovation, efficiency, and competitiveness, helping companies thrive in an increasingly data-driven and automated world.

What are the Common Challenges in Adopting AI in Manufacturing?

While the integration of manufacturing and AI offers immense benefits, it also presents a unique set of challenges. Companies aiming to adopt AI must navigate technical, financial, and organizational hurdles to ensure successful implementation. Understanding these challenges is crucial for developing a realistic and strategic approach to digital transformation in the manufacturing sector.

Data Management and Quality Issues

AI systems rely heavily on high-quality, well-organized data to function effectively. In many manufacturing environments, data is often siloed, inconsistent, or incomplete. Poor data quality can lead to inaccurate AI predictions and flawed automation decisions. Establishing reliable data collection methods and maintaining data integrity are essential for maximizing AI's value.

High Initial Investment and Infrastructure Needs

Implementing AI technologies often requires a significant upfront investment. This includes the cost of new hardware, software, integration with legacy systems, and cloud infrastructure. For small to mid-sized manufacturers, these costs can be a major barrier. Moreover, ongoing maintenance and updates add to the total cost of ownership. Strategic planning and phased implementation can help manage these expenses.

Skill Gaps and Workforce Training

AI adoption demands a workforce with expertise in data science, machine learning, and digital tools—skills that many traditional manufacturing employees may lack. Upskilling and reskilling the existing workforce are critical to ensure smooth integration of AI technologies. In addition, attracting and retaining AI talent remains a challenge for many manufacturers competing in a tight labour market.

Cybersecurity Concerns

With increased digital connectivity and data exchange, manufacturers become more vulnerable to cyber threats. AI systems, if not properly secured, can be targeted by hackers to disrupt operations or steal intellectual property. Strengthening cybersecurity frameworks and implementing robust access controls are essential to protect AI-integrated environments.

In summary, overcoming these challenges is key to unlocking the full potential of AI in manufacturing and ensuring long-term success.

How to Get Started with Manufacturing and Artificial Intelligence?

Getting started with manufacturing and artificial intelligence requires a structured and strategic approach. For manufacturers aiming to modernize operations and stay competitive, understanding where to begin is essential. Below are key steps to guide the successful adoption of AI in manufacturing environments.

Assessing your Manufacturing Needs and Goals

The first step is identifying specific challenges or opportunities where AI can deliver value. Whether it's reducing downtime, improving quality control, or optimizing supply chains, clearly defining your goals helps prioritize the right projects. Conducting a thorough needs assessment ensures alignment between your business objectives and AI initiatives.

Building a Data Strategy for AI Implementation

AI systems are only as good as the data they rely on. Evaluate your current data collection methods and infrastructure. Ensure your data is clean, well-structured, and consistently captured from machines, sensors, and enterprise systems. Establishing a strong data governance framework is essential for accurate AI modelling and analysis.

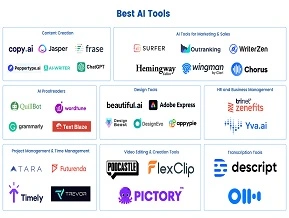

Choosing the Right AI Tools and Technologies

Not all AI tools are suitable for every manufacturing environment. Choose technologies based on your specific use cases, scalability requirements, and integration capabilities. These might include predictive maintenance platforms, computer vision for quality checks, or machine learning for process optimization. Consider cloud-based tools for flexibility and cost-effectiveness.

Collaborating with AI Experts and Partners

Working with AI professionals, technology vendors, or academic partners can accelerate implementation and help avoid common pitfalls. These collaborations bring technical expertise, industry best practices, and training support for your teams, ensuring smoother adoption and long-term success.

By taking these foundational steps, manufacturers can begin their journey into intelligent production systems with confidence and clarity.

What are the Best Learning Resources and Online AI Courses for Manufacturing Professionals?

As AI rapidly reshapes the manufacturing landscape, professionals must stay ahead by continuously updating their skills. Whether you're a factory manager, engineer, or business leader, learning how to apply AI in real-world manufacturing settings is crucial. Here’s a guide to top resources, key skills, and strategies to stay current in this evolving field.

Recommended AI Courses at LAI (Learn Artificial Intelligence)

LAI (Learn Artificial Intelligence) offers beginner-to-advanced courses tailored specifically for manufacturing professionals. Top recommendations include:

- "AI for Smart Manufacturing" – A foundational course that explores AI-driven automation, predictive maintenance, and quality control applications.

- "Machine Learning for Industry 4.0" – Teaches how to build and deploy machine learning models in manufacturing environments.

- "AI-Powered Supply Chain Management" – Focuses on forecasting, demand planning, and logistics optimization.

- "Industrial IoT and AI Integration" – Covers how to connect AI with sensor networks and factory systems.

Each course includes hands-on projects, real-world case studies, and certifications that help learners build practical, job-ready skills.

Key Skills to Develop for AI in Manufacturing

To effectively apply AI in manufacturing, professionals should focus on the following skill areas:

- Data Literacy: Understanding how to collect, clean, and analyse manufacturing data.

- Programming Basics: Familiarity with Python, commonly used for AI applications.

- Machine Learning & Computer Vision: Knowing how AI identifies patterns, detects defects, and improves quality.

- AI Integration: Skills to connect AI tools with ERP, MES, or IoT systems.

How to Stay Updated with AI Trends in Manufacturing?

To keep up with advancements:

- Subscribe to industry blogs, podcasts, and newsletters.

- Join professional communities on LinkedIn or AI forums.

- Attend virtual conferences, webinars, and workshops.

- Regularly check updates from trusted platforms like LAI.

By investing in the right learning paths and staying informed, manufacturing professionals can successfully lead in the AI-driven industrial era.

Conclusion

In today’s fast-evolving industrial landscape, manufacturing and artificial intelligence are driving innovation, efficiency, and smarter decision-making. From predictive maintenance to quality control, the impact is transformative. As we’ve explored, the journey begins with the right knowledge and skills. Whether you're new or experienced, now is the time to embrace the future of manufacturing and AI. Start by exploring expert-led, practical AI courses at LAI (Learn Artificial Intelligence). Equip yourself to lead, adapt, and thrive in the intelligent manufacturing era. Take the first step today—because the factories of tomorrow are being built by the learners of today.