Boosting Efficiency in Logistics and Supply with AI-Powered Solutions

How is Artificial Intelligence Transforming Logistics and Supply Operations?

The logistics and supply industry plays a critical role in global trade and commerce, ensuring that goods move efficiently from point A to point B. As businesses scale and customer expectations continue to rise, the pressure on logistics providers to deliver faster, more accurately, and at lower costs has never been higher. This sector has become increasingly complex, with factors like global disruptions, fuel costs, inventory challenges, and real-time tracking becoming major operational concerns.

To meet these growing demands, companies are turning to technological innovation—and Artificial Intelligence (AI) has emerged as a game-changer. From route optimization and demand forecasting to warehouse automation and real-time tracking, AI is reshaping every stage of the supply chain. It helps organizations reduce operational costs, improve delivery timelines, enhance accuracy, and increase customer satisfaction.

AI’s predictive capabilities allow businesses to anticipate delays, optimize stock levels, and make data-driven decisions with greater confidence. Machine learning algorithms analyse vast amounts of historical and real-time data, enabling smarter planning and agile responses to unforeseen disruptions. Moreover, technologies like autonomous vehicles and AI-powered robotics are streamlining warehouse and transportation tasks, resulting in more resilient and scalable operations.

The purpose of this blog is to explore the various ways AI is improving operations. Whether you're a supply chain manager, logistics professional, or business leader, understanding how AI can transform operational efficiency and decision-making is essential in today’s fast-evolving environment.

In the sections that follow, we will break down specific use cases, real-world examples, and strategic insights into how AI is driving innovation and redefining the future of supply chains.

What Does the Modern Landscape of Logistics and Supply Look Like?

The logistics and supply industry has evolved significantly in recent years, driven by globalization, digital commerce, and rising customer expectations. This complex ecosystem involves the coordination of goods, services, information, and resources from origin to consumption. Key components include procurement, transportation, warehousing, inventory management, and distribution—each playing a critical role in ensuring products reach the right place at the right time.

Key Components of Logistics and Supply

At its core, logistics involves the planning and control of the movement and storage of goods. Supply chain management, on the other hand, covers the broader flow of materials, information, and finances across multiple organizations. Together, these systems create an integrated network of suppliers, manufacturers, distributors, and retailers.

Common Challenges in Today’s Industry

The modern logistics environment is fraught with challenges that can hinder operational efficiency:

- Delivery Delays: Traffic congestion, port bottlenecks, and customs issues can disrupt delivery schedules.

- Inventory Mismanagement: Overstocking or understocking can lead to increased costs or missed sales opportunities.

- Cost Inefficiencies: Rising fuel prices, labour shortages, and inefficient route planning can strain profitability.

These issues are often compounded by unpredictable factors such as geopolitical instability, natural disasters, and shifts in consumer demand.

Why Traditional Methods Fall Short?

In today’s fast-paced and digitally connected world, traditional logistics strategies that rely on manual processes and limited data analytics are no longer sufficient. Static planning tools, fragmented communication, and reactive decision-making create gaps in agility and responsiveness. Businesses need smarter, more adaptive systems to remain competitive.

As a result, companies are increasingly turning to advanced technologies like Artificial Intelligence to address these limitations and drive innovation. The industry is transitioning from reactive logistics to proactive, data-driven operations, setting a new standard for global supply chain performance.

What is AI and Why Does It Matter in Logistics and Supply?

Artificial Intelligence (AI) refers to the ability of machines and computer systems to simulate human intelligence. This includes learning from data, recognizing patterns, making decisions, and improving over time without explicit programming. In simple terms, AI helps computers “think” and act in ways that mimic human reasoning but often faster, more accurately, and at scale.

In the context of logistics and supply, AI is being used to optimize operations, automate repetitive tasks, and enhance decision-making. By analysing vast volumes of data in real-time, AI allows businesses to anticipate issues, streamline processes, and boost productivity.

Key AI Technologies in the Industry

Several AI technologies are especially relevant to the supply chain sector:

- Machine Learning (ML): ML algorithms learn from past data to forecast demand, optimize delivery routes, and detect inefficiencies.

- Computer Vision: Used in warehouses and shipping centres to scan barcodes, track inventory, and inspect goods for damage using cameras and sensors.

- Natural Language Processing (NLP): Enables systems to understand and respond to human language—useful in customer service chatbots or voice-command warehouse systems.

- Predictive Analytics: Combines historical data and AI to predict delays, estimate delivery times, and improve inventory planning.

Benefits of AI Integration

Integrating AI into logistics operations delivers numerous benefits:

- Improved Accuracy: Fewer human errors in inventory management and order processing.

- Faster Deliveries: AI can determine the most efficient shipping routes in real-time.

- Cost Reduction: Automation and optimization lead to lower operational expenses.

- Better Customer Experience: Accurate tracking, timely delivery, and responsive service build customer trust.

AI is not just a trend—it’s a transformative force that is reshaping how businesses manage their operations, creating more agile, responsive, and efficient systems.

How is AI Being Used in Logistics and Supply Management?

Artificial Intelligence is revolutionizing logistics and supply management by introducing smart, data-driven solutions across every stage of the supply chain. From forecasting demand to managing warehouses and optimizing delivery routes, AI is helping businesses enhance efficiency, cut costs, and improve service quality. Below are key use cases demonstrating how AI is reshaping the industry.

AI-Powered Demand Forecasting

AI algorithms analyse historical sales, market trends, seasonal patterns, and external data (like weather or social media) to predict future demand accurately. This enables businesses to plan better, avoid stockouts or overstocking, and align production with actual market needs.

Inventory Optimization with Predictive Analytics

Predictive analytics uses AI to track inventory levels in real-time and forecast replenishment needs. This minimizes waste, reduces carrying costs, and ensures the right products are available at the right time.

Route Optimization and Real-Time Tracking

AI helps logistics providers find the most efficient delivery routes by analysing traffic conditions, weather updates, and delivery schedules. Real-time tracking powered by AI gives both companies and customers full visibility into shipment status, enhancing transparency and trust.

AI in Warehouse Automation and Robotics

AI-driven robots and automated systems streamline warehouse operations, such as picking, sorting, packing, and shelving. This leads to faster fulfilment, reduced labour costs, and fewer errors in order handling.

Smart Procurement and Vendor Management

AI tools can evaluate supplier performance, predict delays, and recommend optimal purchasing decisions. This ensures better vendor relationships and more strategic procurement processes.

Real-World Example

For instance, DHL uses AI to improve last-mile delivery through route optimization and driver assistance tools. Similarly, Amazon relies on AI-powered robots in its fulfilment centres to speed up order processing.

These examples highlight how AI is driving measurable improvements across management, making operations smarter and more resilient.

How Does AI Boost Efficiency in Logistics and Supply Operations?

Artificial Intelligence (AI) is rapidly becoming a cornerstone of efficiency in logistics and supply operations. By leveraging real-time data, predictive analytics, and intelligent automation, AI enables companies to make faster, smarter decisions—ultimately transforming how goods move across the supply chain. Here’s how AI enhances operational performance across key areas:

Real-Time Data Analysis for Faster Decision-Making

AI systems process vast volumes of data from sensors, GPS, and business systems to deliver actionable insights instantly. This allows logistics managers to make quick decisions on routing, inventory levels, and labour allocation—reducing delays and increasing responsiveness.

Reduced Operational Costs and Human Errors

AI automates repetitive and error-prone tasks such as order processing, inventory tracking, and shipment scheduling. By minimizing human involvement in routine processes, companies can reduce costs and eliminate costly errors that disrupt the supply chain.

Improved Customer Satisfaction and Delivery Timelines

Through route optimization, demand forecasting, and real-time tracking, AI ensures accurate and timely deliveries. Customers benefit from reliable service and proactive updates, leading to higher satisfaction and loyalty.

Enhanced Resource Planning and Scalability

AI helps organizations allocate resources—like labour, warehouse space, and fleet capacity—more effectively. Predictive models enable better planning during peak seasons or unexpected disruptions, making operations more scalable and resilient.

Example KPIs Impacted by AI

- Order Accuracy Rate – Higher precision in order fulfilment

- On-Time Delivery Rate – Improved with real-time route optimization

- Inventory Turnover Ratio – Enhanced through smarter inventory planning

- Transportation Cost per Shipment – Lowered through optimized logistics

- Customer Satisfaction Score (CSAT) – Boosted by timely and transparent service

By integrating AI into operations, companies can drive performance improvements across these key metrics—gaining a clear competitive advantage in today’s demanding market.

How Can you Get Started with AI Tools for Logistics and Supply Management?

Embracing AI in logistics and supply management begins with selecting the right tools and platforms that align with your operational goals. From enterprise-grade solutions to customizable models, AI technologies are now more accessible than ever. Here’s how to navigate the options and take the first steps toward AI integration.

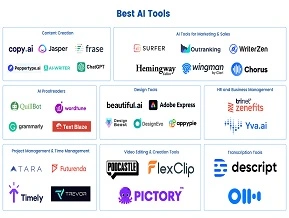

Leading AI Tools and Platforms

Several industry-leading platforms offer AI-powered capabilities tailored to supply chain operations:

- IBM Watson: Delivers AI-driven insights for demand forecasting, route optimization, and real-time visibility across the supply chain.

- SAP Leonardo: Combines AI with IoT and big data to enhance end-to-end supply chain processes, including asset tracking and predictive maintenance.

- Oracle SCM Cloud: Provides intelligent automation for procurement, inventory, logistics, and order management, enabling faster and smarter decisions.

These platforms are designed to streamline operations while integrating seamlessly with enterprise systems.

Integration with Existing ERP Systems

A major advantage of modern AI platforms is their ability to integrate with existing ERP (Enterprise Resource Planning) systems. Whether you're using SAP, Oracle, or Microsoft Dynamics, AI modules can be embedded to enhance functionality without disrupting core operations. This compatibility reduces the friction of adoption and accelerates return on investment.

Custom AI Models vs. SaaS Solutions

Organizations must choose between building custom AI models or adopting ready-to-use SaaS (Software-as-a-Service) solutions. Custom models offer greater flexibility and are ideal for complex, unique supply chains. SaaS platforms, however, are faster to deploy, cost-effective, and require less in-house technical expertise—making them ideal for small to mid-sized companies.

Importance of Data Quality and Infrastructure

No AI system can perform effectively without clean, consistent data. Businesses must invest in high-quality data collection, storage, and processing systems. A robust digital infrastructure is essential to support real-time analytics, sensor data, and AI-driven automation.

By choosing the right tools and building a solid digital foundation, businesses can unlock the full potential of AI in supply management.

What Skills are Needed to Leverage AI in Logistics and Supply?

As Artificial Intelligence (AI) continues to transform business operations across industries, professionals must develop a powerful combination of technical and managerial skills to stay competitive and drive innovation. Understanding how AI works and how to apply it in practical business environments is crucial for success in the modern workforce.

Essential Technical and Managerial Skills

To harness the potential of AI, individuals should focus on the following competencies:

- AI Fundamentals: A basic understanding of machine learning, automation, and AI technologies.

- Data Literacy: The ability to interpret, manage, and analyse data to support informed decision-making.

- Analytics Skills: Using data to forecast, plan, and monitor performance in operational contexts.

- Change Management: Leading teams through digital transformation, addressing resistance, and ensuring smooth implementation.

- Strategic Thinking: Identifying inefficiencies and creating AI-driven solutions to real-world challenges.

Recommended Learning Paths

To build these skills, learners can explore structured programs available through platforms like Learn Artificial Intelligence (LAI). These online courses are designed to teach AI concepts with a focus on real-life applications in business operations and management.

Recommended course areas include:

- AI for Business Decision-Making

- Predictive Analytics and Forecasting

- Automation in Operational Systems

These courses combine theory with hands-on tools, making them highly applicable and career-relevant.

Certifications That Add Value

Enhancing your resume with recognized certifications is a great way to demonstrate AI proficiency. Popular options include:

- Certified AI Practitioner (CAIP)

- Data Science and Machine Learning (Coursera, edX, Udemy)

- AI in Business Strategy (LAI Certificate)

By acquiring the right mix of knowledge and credentials, professionals can confidently lead AI initiatives and unlock new career opportunities.

What are the Future Trends in AI-Powered Logistics and Supply Management?

As technology advances, Artificial Intelligence (AI) is set to revolutionize the way businesses operate in the logistics sector. Emerging innovations will drive efficiency, transparency, and sustainability across supply chains. Here are some of the most impactful trends shaping the future:

Autonomous Delivery Systems

AI-powered drones and self-driving trucks are transforming last-mile and long-distance deliveries. These autonomous solutions reduce reliance on human labour, shorten delivery times, and lower operational costs, enabling faster and more reliable shipping.

Blockchain Integration with AI

The fusion of AI and blockchain technology offers enhanced transparency and security. This combination allows for immutable tracking of goods, improved fraud detection, and real-time data analysis, ensuring greater trust and efficiency within the supply network.

Hyper automation and Intelligent Decision Support

Hyper automation uses AI combined with robotic process automation (RPA) to streamline complex workflows. Intelligent decision support systems analyze large volumes of data to optimize inventory management, route planning, and demand forecasting, empowering businesses to make smarter decisions quickly.

Sustainable Logistics with AI-Driven Carbon Tracking

Environmental sustainability is becoming a priority, and AI plays a crucial role in tracking carbon emissions and promoting greener logistics practices. By optimizing routes and reducing fuel consumption, companies can meet sustainability targets while maintaining operational efficiency.

By embracing these trends, companies can transform their logistics and supply management operations to be more agile, transparent, and environmentally responsible—preparing them for the challenges of tomorrow’s market.

Conclusion

AI is undeniably transforming the logistics and supply industry by driving greater efficiency, accuracy, and sustainability across operations. Its ability to optimize demand forecasting, automate processes, and provide real-time insights is reshaping how businesses manage complex logistics and supply management challenges. To stay competitive in this rapidly evolving landscape, professionals must proactively upskill and embrace AI technologies. Enrolling in specialized AI courses designed for the logistics sector is a smart way to build relevant expertise. We encourage you to explore the comprehensive course offerings at LAI, where you can gain practical knowledge and tools to lead the future of operations with confidence.