Artificial Intelligence in Logistics Optimizing Route Planning and Inventory Management

Artificial intelligence in logistics is revolutionising the management, transportation, and delivery of goods worldwide. With the fast-paced evolution of technology, AI is increasingly being used to enhance operational efficiency, improve accuracy, and support data-driven decision-making across the logistics sector. In this context, AI involves the application of machine learning, data analytics, and automation tools to optimise core processes such as inventory control, route optimisation, demand forecasting, and warehouse management. The growing reliance on AI is evident as logistics companies strive for faster deliveries, lower operational costs, and enhanced customer experiences. Advanced AI systems offer capabilities like real-time tracking, predictive maintenance, and intelligent warehousing, which are redefining traditional supply chain practices. Furthermore, AI provides solutions to persistent industry challenges including delivery delays, stock inaccuracies, workforce shortages, and unpredictable demand shifts. The integration of logistics and AI not only improves operational responsiveness but also supports the development of smarter, more efficient supply chains.

How is Artificial Intelligence Transforming Route Planning in Logistics?

Artificial intelligence in logistics is rapidly reshaping the landscape of route planning by enabling smarter, faster, and more efficient delivery systems. Traditional route planning relied heavily on static maps, fixed schedules, and the manual experience of drivers. These methods often failed to account for real-time disruptions such as traffic congestion, road closures, or weather changes. In contrast, AI-powered route optimisation systems use real-time data and advanced algorithms to make dynamic, data-driven decisions that enhance delivery performance and reduce operational costs.

Traditional Route Planning vs AI-Powered Route Optimisation

Traditional route planning typically involved pre-set routes created using historical data or human judgment. These methods lacked flexibility and often led to delays, increased fuel consumption, and poor customer satisfaction. On the other hand, AI-powered systems analyse vast amounts of real-time and historical data to determine the most efficient routes. They automatically adjust delivery plans to accommodate last-minute changes, ensuring timely and cost-effective logistics operations.

Role of Machine Learning and Data Analytics in Route Planning

Machine learning and data analytics are at the core of AI-based route planning. These technologies process enormous volumes of data, including delivery locations, vehicle capacities, customer time windows, traffic patterns, and weather conditions. Machine learning models learn from past outcomes to continually improve future routing decisions. By analysing trends and identifying inefficiencies, AI helps logistics companies make smarter routing choices and improve performance over time.

Real-Time Traffic Analysis and Dynamic Routing with AI

AI systems integrate GPS data, traffic sensors, and other real-time inputs to monitor road conditions continuously. When unexpected events like accidents or road closures occur, AI dynamically re-routes deliveries to avoid delays. This real-time adaptability ensures that goods arrive on time and helps companies maintain high levels of service reliability.

Benefits of AI-Driven Route Planning: Cost Savings, Efficiency, and Delivery Speed

AI-driven route planning delivers multiple benefits, including reduced fuel consumption, lower labour costs, improved driver productivity, and faster delivery times. By minimising idle time and optimising travel routes, companies achieve significant cost savings while enhancing customer satisfaction. Ultimately, the integration of artificial intelligence in logistics leads to smarter, more agile, and sustainable delivery networks.

Artificial Intelligence in Inventory Management: Revolutionizing Supply Chain Efficiency

Artificial intelligence in logistics is playing a transformative role in inventory management, addressing long-standing inefficiencies and enabling smarter, data-driven decision-making across the supply chain. As the demand for real-time visibility and accuracy grows, AI is revolutionising how businesses forecast demand, manage stock levels, and optimise warehouse operations.

Challenges in Traditional Inventory Management

Traditional inventory management systems often rely on manual tracking, static spreadsheets, and historical sales data. These methods are prone to errors, delays, and inefficiencies. Common challenges include inaccurate demand forecasting, delayed replenishment, stock outs, and overstocking—all of which can lead to lost sales or increased holding costs. Without real-time insights, businesses struggle to respond quickly to market fluctuations or customer demand changes.

AI Techniques Used in Inventory Forecasting and Demand Prediction

AI leverages machine learning algorithms and predictive analytics to improve inventory forecasting accuracy. These systems analyse historical sales trends, seasonality, market behaviour, and external factors like weather and promotions to predict future demand with greater precision. As a result, companies can plan inventory more effectively and reduce the risks associated with over- or under-stocking.

Automated Stock Replenishment and Warehouse Optimization Using AI

AI-powered systems can automate stock replenishment by monitoring inventory levels in real-time and triggering orders when stock falls below set thresholds. These systems consider lead times, supplier performance, and demand patterns to optimise reorder quantities and timing. In warehouses, AI enhances layout planning, picking efficiency, and stock placement through the use of robotics, computer vision, and IoT devices. This leads to faster fulfilment, reduced labour costs, and better space utilisation.

Impact of AI on Reducing Stock outs and Overstocking

By improving forecasting and automating replenishment, AI significantly reduces the risk of stock outs and excess inventory. Businesses can maintain optimal stock levels, minimise waste, and enhance customer satisfaction through timely and accurate order fulfilment. The integration of artificial intelligence in logistics allows companies to move from reactive to proactive inventory management, boosting supply chain resilience and efficiency in an increasingly dynamic market.

Key Technologies Driving AI Applications in Logistics

Artificial intelligence in logistics is revolutionising how supply chains operate by integrating cutting-edge technologies that enhance efficiency, accuracy, and decision-making. These technologies work together to automate processes, provide real-time insights, and streamline logistics operations from warehousing to last-mile delivery. Below are some of the key technologies that are driving AI applications in the logistics sector.

Machine Learning and Predictive Analytics

Machine learning forms the backbone of many AI-driven logistics solutions. By analysing historical and real-time data, machine learning algorithms can identify patterns and predict future events such as delivery times, demand spikes, and potential disruptions. Predictive analytics allows companies to forecast inventory needs, optimise routes, and reduce delivery delays, ultimately improving customer satisfaction and operational efficiency.

Internet of Things (IoT) Integration for Real-Time Data

IoT devices play a crucial role in collecting real-time data from vehicles, warehouses, and shipping containers. Sensors track variables like temperature, humidity, location, and vehicle performance, feeding this data into AI systems for analysis. With IoT integration, logistics managers gain enhanced visibility over their supply chain, enabling proactive decision-making and quicker responses to unexpected changes or disruptions.

Robotics and Automation in Warehouses

AI-powered robotics and automation technologies are transforming warehouse operations. Autonomous mobile robots (AMRs) handle tasks such as picking, packing, and transporting goods, significantly reducing human error and labour costs. AI systems coordinate robotic movements and optimise workflows, leading to faster processing times and improved order accuracy. Automation also enables 24/7 warehouse operations, increasing overall productivity.

AI-Powered Decision Support Systems

AI-driven decision support systems analyse large volumes of logistics data to offer strategic recommendations. These systems assist with resource allocation, route planning, inventory management, and risk assessment. By providing data-backed insights, AI supports better decision-making, allowing businesses to adapt swiftly to market changes and customer needs.

The integration of artificial intelligence in logistics through these advanced technologies is creating smarter, more agile, and resilient supply chains. As AI continues to evolve, its role in driving innovation and competitiveness in the logistics industry will only grow stronger.

Benefits of Integrating AI in Logistics and Supply Chain Management

Artificial intelligence in logistics is reshaping the future of supply chain management by offering innovative solutions that enhance performance, reduce costs, and deliver superior customer experiences. Through automation, real-time data analysis, and intelligent decision-making, AI helps companies gain a competitive edge in a rapidly evolving market. Below are some of the key benefits of integrating AI into logistics and supply chain operations.

Improved Accuracy and Efficiency

AI significantly improves operational accuracy by reducing human errors and automating repetitive tasks. Machine learning algorithms and predictive analytics enhance forecasting, inventory management, and route planning. This results in fewer stock discrepancies, timely deliveries, and more accurate order fulfilment. Real-time monitoring of logistics activities also ensures that potential issues are identified and resolved quickly, boosting overall efficiency.

Cost Reduction and Resource Optimization

One of the most significant advantages of using AI in logistics is cost reduction. AI helps companies optimise fuel usage, labour, and storage space by analysing data and providing smart recommendations. Automated systems reduce the need for manual intervention, lowering operational expenses. Additionally, AI can identify inefficiencies in the supply chain and suggest improvements, enabling better resource allocation and reduced waste.

Enhanced Customer Satisfaction through Faster Deliveries

Customer expectations for quick and reliable delivery continue to rise. AI supports this demand by streamlining processes such as route optimisation, real-time tracking, and warehouse automation. Faster deliveries and improved accuracy lead to higher customer satisfaction and increased loyalty. AI-powered chatbots and customer support tools also enhance communication and provide timely updates to customers.

Increased Scalability and Flexibility of Logistics Operations

As businesses grow, logistics operations must scale accordingly. AI provides the flexibility needed to adapt to fluctuating demand, seasonal spikes, and market changes. Intelligent systems can adjust resources and strategies in real-time, allowing companies to scale operations efficiently. This agility ensures that businesses remain responsive and resilient in a dynamic global market.

The integration of artificial intelligence in logistics empowers companies to build smarter, more responsive, and cost-effective supply chains, setting the stage for long-term success.

Challenges and Considerations in Implementing AI in Logistics

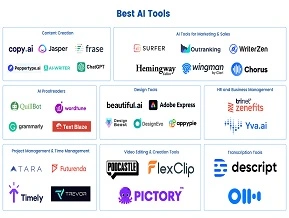

While AI offers transformative potential for the logistics industry, its implementation is not without challenges. Logistics companies must carefully evaluate various technical, operational, and ethical aspects before fully embracing artificial intelligence. As with AI content creation tools, adopting AI in logistics requires strategic planning, investment, and a focus on quality and security. Below are some key challenges and considerations.

Data Quality and Integration Issues

AI systems rely heavily on large volumes of accurate and well-structured data to function effectively. In logistics, data often comes from diverse sources such as warehouse systems, transportation platforms, and customer service databases. Ensuring consistency, accuracy, and completeness across these systems can be difficult. Poor data quality can lead to incorrect predictions, inefficiencies, and reduced AI performance. Integrating data from legacy systems into modern AI platforms also presents a significant hurdle for many logistics firms.

Technological and Infrastructure Investments

Implementing AI in logistics requires significant technological infrastructure, including cloud computing, IoT sensors, robotics, and advanced software platforms. These investments can be expensive, especially for small to mid-sized companies. Businesses must also plan for system upgrades, maintenance, and potential disruptions during implementation. The cost of acquiring or developing AI algorithms and maintaining up-to-date technologies is an ongoing consideration.

Workforce Adaptation and Training Needs

As AI automates many routine tasks, the workforce must adapt to new roles focused on supervising, managing, and optimising AI-driven systems. Employees will need reskilling and up skilling in areas such as data analysis, digital tools, and AI oversight. Resistance to change, lack of technical skills, and fear of job displacement can hinder successful adoption. Companies must invest in training programmes and foster a culture of continuous learning.

Ethical and Security Concerns

Just like with AI content creation tools, ethical use and data security are critical considerations in logistics. AI systems must be transparent, unbiased, and secure. Ensuring the ethical handling of customer and business data, preventing data breaches, and maintaining compliance with regulations are all essential for responsible AI deployment.

Addressing these challenges effectively is key to unlocking the full benefits of AI in logistics while ensuring sustainable and secure growth.

Future Trends: The Evolving Role of AI in Logistics

As the logistics industry continues to evolve, artificial intelligence is becoming increasingly central to its transformation. Just as AI content creation tools are revolutionising digital marketing and publishing, AI technologies are reshaping logistics by driving innovation, sustainability, and operational excellence. The following trends highlight how AI will continue to shape the future of logistics.

Emerging AI Innovations in Logistics

New and emerging AI technologies are streamlining logistics operations with greater intelligence and autonomy. Advanced algorithms now enable real-time decision-making, enhanced demand forecasting, and adaptive route optimisation. Innovations like natural language processing and computer vision are also being used for automated documentation, cargo recognition, and monitoring shipments in real-time. These technologies promise to further reduce costs, improve accuracy, and boost speed across the supply chain.

Predictive and Prescriptive Logistics Management

Predictive analytics, a core function of AI, enables logistics providers to forecast demand, identify potential delays, and proactively manage inventory. Going a step further, prescriptive analytics recommends optimal actions based on predictive insights, helping businesses make better strategic and operational decisions. This shift from reactive to proactive logistics management leads to greater efficiency and customer satisfaction.

AI in Sustainable and Green Logistics Practices

Environmental sustainability is becoming a major focus in logistics. AI supports green logistics through optimised routing that reduces fuel consumption and emissions, intelligent packaging to minimise waste, and energy-efficient warehouse automation. Smart algorithms can also assess the carbon footprint of each supply chain operation and suggest eco-friendly alternatives. AI’s ability to manage complex sustainability data will play a pivotal role in achieving greener logistics solutions.

Potential Impact of AI-Powered Autonomous Vehicles and Drones

Autonomous delivery vehicles and drones, powered by AI, represent a significant shift in how goods are transported. These technologies offer the promise of 24/7 deliveries, reduced labour dependency, and faster last-mile services. While still in the early stages, their integration into logistics networks is expected to grow, especially in urban areas and remote locations.

Much like the innovation seen with AI content creation tools, the future of logistics lies in intelligent, data-driven automation that boosts performance while addressing sustainability and customer demands.

Conclusion

Content Creation Tools in AI have demonstrated how powerful and transformative artificial intelligence can be across industries—and logistics is no exception. From optimising route planning to revolutionise inventory management, AI is driving faster, smarter, and more efficient supply chains. These technologies are reshaping traditional logistics models and empowering organisations to stay competitive in an increasingly digital world. To fully harness the benefits of AI, logistics professionals must stay informed and skilled. Understanding tools, data systems, and automation processes is essential. Like learning how to use AI content creation tools, mastering logistics AI solutions requires proper education and training. Logistics professionals are encouraged to explore dedicated AI courses at LAI. These programmes are designed to equip learners with practical knowledge to leverage the latest AI innovations and transform logistics operations for a smarter, future-ready industry. Embracing AI today means preparing for a more agile, efficient, and competitive logistics future.