Artificial Intelligence for Logistics: How AI is Transforming Supply Chain Operations?

Artificial intelligence for logistics is rapidly transforming global supply chains by enhancing efficiency, accuracy, and decision-making. In today’s complex logistics environment, AI technologies streamline processes such as inventory management, route optimization, and demand forecasting, which helps reduce costs and improve customer satisfaction. The growing impact of logistics with AI allows companies to respond more quickly to market changes, predict potential disruptions, and automate routine tasks—critical factors in today’s fast-paced global economy where speed and precision are key competitive advantages. To support professionals and learners in mastering these advancements, LAI offers specialized courses designed to equip students with the knowledge needed to harness AI effectively in logistics. Through practical lessons and expert guidance, LAI ensures learners gain a solid understanding of real-world AI applications that drive innovation and success in supply chain management.

What is Artificial Intelligence for Logistics? Understanding the Basics

Defining Artificial Intelligence for Logistics

Artificial intelligence for logistics refers to the use of advanced AI technologies to optimize and automate various processes within the supply chain and logistics management. It involves leveraging machine learning algorithms, computer vision, and data analytics to improve decision-making, predict demand, and enhance operational efficiency. AI in logistics aims to reduce costs, minimize errors, and increase overall productivity by enabling smarter and faster solutions.

Key AI Technologies Used in Logistics

Several AI technologies play a vital role in transforming logistics operations. Machine learning helps analyse vast amounts of data to predict demand, optimize routes, and manage inventory. Computer vision technology enables real-time tracking, quality control, and automated sorting in warehouses. Additionally, the integration of the Internet of Things (IoT) with AI allows for continuous monitoring of goods in transit, vehicle conditions, and warehouse environments, providing valuable insights to improve logistics processes.

The Importance of AI in Modern Supply Chain Management

In today’s fast-paced and highly competitive market, AI is essential for modern supply chain management. It helps companies respond quickly to changes in demand, avoid disruptions, and streamline workflows. With artificial intelligence for logistics, businesses can achieve greater accuracy in forecasting, improve delivery times, and reduce waste. This not only enhances customer satisfaction but also boosts profitability. As supply chains become more complex, AI-driven logistics solutions are becoming a critical component for companies looking to stay ahead in the industry.

By understanding the basics of artificial intelligence for logistics, professionals can better appreciate how AI technologies are revolutionizing the field and driving efficiency across global supply networks.

How is Logistics with AI Revolutionising Supply Chain Operations?

AI Applications Transforming Logistics

Artificial intelligence for logistics is revolutionising supply chain operations by enabling smarter, faster, and more efficient processes. One key application is demand forecasting, where AI analyses historical data and market trends to predict future customer demand accurately. This helps companies optimize inventory levels, reduce stock outs, and minimize excess inventory costs. Route optimization is another critical area where AI uses real-time traffic data, weather conditions, and delivery constraints to plan the most efficient delivery routes, cutting down fuel consumption and delivery times.

Real-Time Data Analytics and Predictive Maintenance

Logistics with AI leverages real-time data analytics to provide up-to-the-minute insights across the supply chain. Sensors connected through IoT devices continuously monitor vehicles, equipment, and inventory conditions. AI-powered predictive maintenance analyses this data to forecast equipment failures before they happen, reducing downtime and costly repairs. This proactive approach helps maintain smooth operations and extends the lifespan of logistics assets.

Automation in Warehousing and Distribution Centres

Automation driven by artificial intelligence for logistics is transforming warehousing and distribution centres. AI-powered robots and automated guided vehicles (AGVs) perform repetitive tasks such as sorting, picking, and packing with high accuracy and speed. Computer vision systems inspect goods for quality assurance, while AI algorithms manage warehouse space efficiently, ensuring optimal storage and retrieval. This automation reduces human error, improves safety, and boosts overall productivity.

By integrating these AI-driven solutions, logistics companies are not only enhancing operational efficiency but also gaining a competitive advantage in a rapidly evolving market. Logistics with AI is shaping the future of supply chain management by delivering smarter, more responsive, and sustainable operations.

Key Benefits of Using Artificial Intelligence for Logistics

Increased Operational Efficiency and Cost Reduction

One of the primary advantages of artificial intelligence for logistics is the significant boost in operational efficiency. AI technologies automate routine tasks such as inventory management, order processing, and shipment scheduling, allowing logistics companies to reduce manual labour and minimize human error. By optimizing routes and improving warehouse workflows, AI helps cut fuel consumption and reduce transportation costs. These efficiencies translate into substantial cost savings across the supply chain.

Enhanced Accuracy in Inventory and Delivery Tracking

Artificial intelligence for logistics enables precise tracking of inventory levels and shipments in real time. Using advanced sensors, IoT devices, and AI-powered analytics, businesses gain complete visibility into their supply chain. This accuracy ensures that inventory is maintained at optimal levels, reducing stock outs and overstock situations. Additionally, AI-driven delivery tracking provides timely updates and alerts, allowing companies to manage exceptions proactively and ensure shipments reach their destinations on schedule.

Improved Customer Satisfaction through Faster, Reliable Deliveries

Faster and more reliable deliveries are key drivers of customer satisfaction in today’s market. AI in logistics streamlines the entire delivery process—from warehouse management to last-mile delivery—ensuring that customers receive their orders promptly. AI-powered route optimization reduces delays caused by traffic or weather, while predictive analytics anticipate demand spikes, enabling companies to prepare accordingly. These capabilities build trust and loyalty among customers.

Risk Management and Supply Chain Resilience

Artificial intelligence for logistics also plays a crucial role in risk management and enhancing supply chain resilience. By analysing large volumes of data, AI can identify potential risks such as supplier disruptions, transportation delays, or geopolitical issues. Predictive models help companies develop contingency plans and adapt quickly to unexpected challenges. This proactive approach strengthens the supply chain, making it more flexible and capable of withstanding disruptions.

In summary, the integration of artificial intelligence for logistics delivers measurable benefits across operations, accuracy, customer experience, and risk management—making it a vital tool for modern supply chains.

AI Technologies Driving Logistics with AI Innovations

Autonomous Vehicles, Drones, and AI-Powered Robots in Logistics

Artificial intelligence for logistics is being propelled forward by cutting-edge technologies such as autonomous vehicles, drones, and AI-powered robots. Autonomous trucks and delivery vehicles are increasingly used to transport goods with minimal human intervention, improving efficiency and reducing operational costs. Drones are revolutionizing last-mile delivery by enabling rapid transport of small parcels, especially in hard-to-reach areas. Meanwhile, AI-powered robots are transforming warehousing by automating picking, packing, and sorting tasks, enhancing speed and accuracy within distribution centres.

Machine Learning Models for Demand Prediction and Supply Chain Optimization

Machine learning plays a pivotal role in logistics innovation by enabling more accurate demand forecasting and supply chain optimization. These models analyse historical data, seasonal trends, and external factors such as market conditions or weather to predict future demand patterns. This insight helps companies optimize inventory levels, reduce waste, and improve order fulfilment. Additionally, machine learning algorithms optimize routes and delivery schedules by dynamically adjusting to real-time conditions, leading to reduced fuel consumption and faster deliveries.

Integration of AI with IoT for Real-Time Monitoring

The combination of artificial intelligence for logistics and Internet of Things (IoT) devices offers unprecedented real-time monitoring capabilities. Sensors embedded in vehicles, containers, and warehouses continuously collect data on temperature, humidity, location, and equipment status. AI analyses this data to provide actionable insights, such as detecting equipment malfunctions before they cause delays or identifying bottlenecks in the supply chain. This integration enhances visibility and responsiveness, allowing logistics managers to make data-driven decisions quickly.

In conclusion, artificial intelligence for logistics leverages autonomous systems, machine learning, and IoT integration to revolutionize supply chain management. These innovations lead to smarter, faster, and more efficient logistics operations, shaping the future of global supply chains.

Challenges in Implementing Artificial Intelligence for Logistics

Data Quality and Integration Issues

One of the primary challenges in adopting logistics with AI is ensuring high-quality and well-integrated data. AI systems rely heavily on large volumes of accurate, consistent, and real-time data to deliver effective insights. However, logistics operations often involve data from multiple sources and formats—ranging from inventory databases to GPS tracking and supplier records—which can create complexities in data integration. Poor data quality or fragmented data systems can reduce AI accuracy, leading to suboptimal decisions and inefficiencies.

High Initial Investment and Technology Adoption Barriers

Implementing AI technologies in logistics requires substantial upfront investment in infrastructure, software, and training. Many organizations face financial constraints or hesitate to adopt new AI tools due to uncertainty about their return on investment. Additionally, integrating AI into existing legacy systems can be complex and time-consuming, deterring some companies from moving forward quickly. Overcoming these barriers requires strategic planning and often staged adoption to balance cost with gradual benefits.

Workforce Adaptation and Skill Development

The shift to logistics with AI demands new skills from the workforce, including data analysis, AI system management, and technology troubleshooting. Employees may resist changes due to fear of job displacement or unfamiliarity with AI tools. Organizations must invest in comprehensive training programs to up skill their teams and foster a culture of continuous learning. Successful adaptation hinges on combining human expertise with AI capabilities, rather than replacing the human element.

Ethical and Regulatory Considerations

Ethical issues such as data privacy, bias in AI decision-making, and transparency also pose challenges for AI implementation in logistics. Companies must ensure compliance with regulations governing data protection and responsible AI use. Moreover, as AI systems make increasingly critical decisions, establishing accountability and addressing potential biases in algorithms becomes essential to maintain trust and fairness in logistics operations.

In summary, while logistics with AI offers transformative benefits, organizations must navigate challenges related to data, costs, workforce readiness, and ethics to realize its full potential effectively.

How Can You Learn Artificial Intelligence for Logistics with LAI?

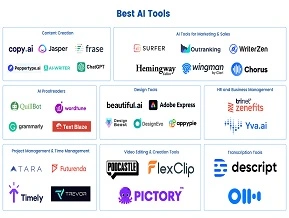

Recommended Courses and Learning Paths at LAI

LAI offers specialized courses designed to help learners master logistics with AI by focusing on practical applications of artificial intelligence in supply chain management. These courses cover key topics such as AI-driven demand forecasting, route optimization, inventory management, and automation technologies. Whether you are a beginner or an experienced professional, LAI’s structured learning paths provide a clear roadmap to develop your skills progressively. The curriculum is tailored to ensure that students gain both theoretical knowledge and practical insights into AI’s role in modern logistics.

Hands-On Projects and Real-World Case Studies

To reinforce learning, LAI incorporates hands-on projects and case studies that simulate real-world logistics challenges solved using AI. Students get the opportunity to work with AI-powered tools and platforms, applying machine learning models to optimize supply chains or improve warehouse operations. These interactive experiences not only build confidence but also prepare learners to implement AI solutions effectively in their workplace. By engaging in practical exercises, students develop critical problem-solving skills and a deep understanding of how AI transforms logistics processes.

Staying Updated on AI Logistics Trends and Technologies

The field of logistics with AI is rapidly evolving, making continuous learning essential. LAI provides learners with access to up-to-date resources, including research articles, webinars, and industry reports on the latest AI trends and technological advancements in logistics. This ongoing support helps professionals stay informed about emerging tools like autonomous vehicles, IoT integrations, and AI-powered predictive analytics. By staying current, learners can adapt quickly and leverage new innovations to enhance supply chain efficiency and resilience.

In summary, LAI’s comprehensive approach to teaching logistics with AI combines expert instruction, practical experience, and continuous learning resources. This ensures that students are well-prepared to harness AI effectively and drive innovation in the logistics sector.

The Future of Logistics with AI: Trends to Watch in 2025 and Beyond

Emerging Trends: Hyper automation and AI-Driven Supply Chain Networks

In 2025 and beyond, logistics with AI is set to advance through hyper automation—combining AI, robotic process automation, and advanced analytics to automate end-to-end supply chain operations. This integration will enable companies to create fully connected, intelligent supply chain networks that respond dynamically to real-time data. AI-powered systems will optimize everything from inventory replenishment to transportation scheduling, reducing manual intervention and increasing overall efficiency.

AI’s Growing Role in Sustainability and Green Logistics

Sustainability is becoming a top priority in logistics, and AI plays a crucial role in promoting green logistics practices. By leveraging AI-driven analytics, companies can minimize fuel consumption, reduce emissions, and optimize routes for eco-friendly deliveries. Additionally, AI helps in better resource management, such as energy-efficient warehouse operations and waste reduction. This focus on sustainability through logistics with AI supports corporate social responsibility goals while also cutting operational costs.

Predictions on AI’s Evolving Impact on Global Logistics

Looking ahead, AI will continue to reshape global logistics by enhancing supply chain visibility, enabling predictive maintenance of vehicles and equipment, and facilitating smarter decision-making across the entire logistics ecosystem. The rise of autonomous vehicles and drones, powered by AI, is expected to transform last-mile delivery and distribution. Furthermore, AI-driven risk management tools will help companies anticipate disruptions and improve resilience against global challenges like pandemics or geopolitical events.

Overall, logistics with AI promises to revolutionize the supply chain landscape, making it more efficient, sustainable, and adaptable. Organizations that invest in these AI technologies will gain a competitive edge by meeting the demands of an increasingly complex and fast-paced global market. Staying informed and prepared for these trends is essential for professionals aiming to lead in the future of logistics.

Conclusion

Artificial intelligence for logistics is fundamentally transforming supply chains worldwide by enhancing efficiency, accuracy, and decision-making processes. This powerful technology enables smarter management of inventory, transportation, and customer fulfilment, resulting in faster deliveries, reduced costs, and stronger supply chain resilience. As the logistics industry continues to evolve, developing skills in logistics with AI becomes essential for professionals who want to remain competitive and drive innovation. Mastering these AI technologies opens up new career opportunities and empowers individuals to make significant impacts within their organizations. To stay ahead and lead the future of logistics, explore LAI’s specialized courses focused on artificial intelligence for logistics. These programs offer practical knowledge and hands-on experience, equipping learners to harness AI effectively and become pioneers in this rapidly advancing field. Begin your journey with LAI today and position yourself at the forefront of logistics innovation.