Artificial Intelligence and Supply Chain: How AI is Optimizing Inventory and Demand?

Artificial intelligence and supply chain management are becoming increasingly interconnected, ushering in a new era of efficiency and innovation in the movement of goods and services from origin to customer. By leveraging advanced algorithms and data analytics, AI optimizes complex supply chain processes such as inventory management, demand forecasting, and logistics. The integration of supply chain with AI is transforming traditional operations by enabling real-time decision-making, reducing costs, and enhancing overall responsiveness. AI-powered tools allow businesses to predict market demands more accurately, streamline procurement processes, and improve delivery routes. Optimizing inventory and demand forecasting is essential to prevent issues like overstocking or stockouts, which can cause lost revenue and customer dissatisfaction. AI technologies analyse historical data and current market trends to deliver precise forecasts, ensuring that supply chains remain agile, efficient, and competitive in today’s fast-paced business environment.

The Role of Supply Chain with AI in Inventory Management

Effective inventory management is a critical component of successful supply chain operations. With the integration of artificial intelligence and supply chain management, businesses can significantly improve accuracy, efficiency, and responsiveness in handling inventory.

Improving Accuracy in Inventory Tracking and Control

AI-powered systems use advanced sensors, RFID technology, and machine learning algorithms to monitor inventory levels in real time. These technologies minimize human error by automating data capture and analysis, providing highly accurate and up-to-date information about stock availability. This precise tracking helps businesses maintain optimal inventory levels, avoid costly errors, and streamline warehouse operations.

Real-Time Inventory Visibility Using AI-Powered Tools

One of the most transformative benefits of AI in supply chains is real-time inventory visibility. AI platforms consolidate data from various sources, including warehouses, suppliers, and retail locations, offering a unified dashboard for inventory status. This instant visibility enables supply chain managers to make informed decisions quickly, respond to demand fluctuations, and manage replenishment more effectively. Real-time insights also improve collaboration between different supply chain partners, enhancing overall efficiency.

Reducing Overstock and Stockouts through Predictive Analytics

Overstocking ties up capital and storage resources, while stockouts lead to missed sales and dissatisfied customers. AI addresses these challenges by employing predictive analytics to forecast demand accurately. By analysing historical sales data, seasonal trends, and external factors like market conditions or weather, AI models predict future inventory needs with greater precision. This foresight allows companies to balance stock levels, reduce waste, and improve customer satisfaction.

In summary, the integration of artificial intelligence and supply chain functions in inventory management is revolutionizing how companies monitor, control, and optimize their stock. These advancements are essential for businesses aiming to maintain competitive advantage in today’s fast-moving market.

Demand Forecasting Enhanced by Artificial Intelligence and Supply Chain Integration

Accurate demand forecasting is crucial for efficient supply chain management. The integration of artificial intelligence and supply chain processes has revolutionized how businesses predict and plan for customer demand, allowing for smarter decision-making and improved operational efficiency.

AI Models for Analysing Historical Sales and Market Trends

AI leverages vast amounts of historical sales data, along with external market trends, to provide comprehensive insights into future demand. These models analyse patterns such as seasonality, consumer behaviour, and economic indicators to detect subtle shifts in demand that traditional forecasting methods may overlook. By processing this complex data quickly and accurately, AI helps businesses anticipate changes and adjust their supply chain strategies proactively.

Machine Learning Techniques for Accurate Demand Prediction

Machine learning, a subset of AI, plays a pivotal role in demand forecasting by continuously learning from new data and refining its predictions. Algorithms like regression analysis, neural networks, and time-series forecasting adapt to evolving market conditions, reducing forecasting errors and increasing precision. This dynamic learning capability allows companies to respond swiftly to fluctuations, optimize inventory levels, and avoid costly overstock or stockouts.

Case Studies Showing Improved Demand Planning with AI

Several leading companies have demonstrated significant improvements in demand planning through AI integration. For example, retail giants have reported reduced inventory costs and improved product availability by using AI-driven forecasts to manage stock more effectively. In manufacturing, AI-enabled demand forecasting has streamlined production schedules, ensuring resources are allocated efficiently and minimizing waste.

In conclusion, the combination of artificial intelligence and supply chain technologies in demand forecasting empowers businesses to enhance accuracy, reduce operational risks, and increase customer satisfaction. As AI continues to advance, its role in demand planning will become even more critical in driving supply chain excellence and competitive advantage.

AI Technologies Revolutionizing Supply Chain with AI

The integration of artificial intelligence and supply chain technologies is driving transformative changes in how businesses manage their operations. Cutting-edge innovations such as the Internet of Things (IoT), big data analytics, robotics, and AI are collectively enhancing supply chain efficiency, accuracy, and speed.

IoT, Big Data, and AI in Supply Chain Analytics

The Internet of Things (IoT) connects devices and sensors across the supply chain, generating vast amounts of real-time data. When combined with big data analytics and AI, this information provides unparalleled visibility into inventory levels, shipment status, and equipment health. AI algorithms analyse these massive datasets to identify patterns, predict disruptions, and optimize decision-making processes. This integration allows companies to anticipate demand fluctuations, manage risks, and reduce operational costs.

Automated Warehouses and Robotics in Inventory Handling

Automation powered by AI is transforming warehouse operations. Robotics systems are now capable of handling inventory tasks such as picking, packing, and sorting with high speed and precision. Automated guided vehicles (AGVs) and robotic arms reduce human error and increase throughput, enabling 24/7 operations. These advancements not only improve inventory accuracy but also enhance workplace safety and reduce labour costs.

AI-Driven Logistics Optimization for Faster Delivery

Logistics, a critical component of the supply chain, benefits significantly from AI-driven optimization tools. AI algorithms optimize delivery routes by considering traffic, weather, and customer preferences in real time, ensuring faster and more reliable shipments. Additionally, predictive analytics help forecast delays and enable proactive rerouting to avoid bottlenecks. This leads to improved customer satisfaction and reduced transportation expenses.

In summary, the fusion of artificial intelligence and supply chain technologies such as IoT, big data, robotics, and AI-driven logistics is revolutionizing supply chain management. These innovations create smarter, more agile, and cost-effective supply chains capable of meeting the demands of today’s fast-paced markets.

Benefits of Artificial Intelligence and Supply Chain Optimization

Integrating supply chain with AI offers numerous advantages for modern businesses aiming to stay competitive in an increasingly dynamic marketplace. From cost savings and improved efficiency to enhanced customer experiences and greater operational agility, AI has become a cornerstone in supply chain innovation.

Increased Efficiency and Cost Savings

One of the most significant benefits of incorporating AI into supply chain operations is the boost in overall efficiency. AI-driven automation reduces manual tasks, streamlines procurement, and enhances inventory management. Algorithms can analyse data to identify bottlenecks and recommend faster, cheaper alternatives for sourcing and logistics. As a result, companies can lower operational costs, reduce waste, and optimise the use of resources without compromising quality or speed.

Enhanced Customer Satisfaction through Better Product Availability

Maintaining optimal stock levels is critical to meeting customer demands promptly. By integrating supply chain with AI, businesses can use predictive analytics to forecast demand with high accuracy. This enables timely restocking, minimises the risk of stockouts, and ensures that the right products are available at the right time. Improved fulfilment rates and faster delivery times lead to increased customer satisfaction and loyalty, which are essential for long-term success.

Agility and Resilience in Supply Chain Operations

In today’s unpredictable business environment, agility and resilience are vital. AI empowers supply chains to adapt quickly to changing market conditions, disruptions, or consumer preferences. Real-time monitoring and analytics allow businesses to detect issues early, re-route shipments, or adjust production plans proactively. This flexibility helps mitigate risks and ensures continuity, even during crises like natural disasters, pandemics, or global supply shortages.

In conclusion, leveraging supply chain with AI unlocks a wide range of benefits, including operational efficiency, cost-effectiveness, better customer service, and increased resilience. Companies that embrace these technologies are well-positioned to thrive in a competitive global market, delivering value both to their customers and their bottom line.

Challenges and Considerations When Implementing Supply Chain with AI

Adopting a supply chain with AI can offer transformative benefits, but it also presents several challenges and considerations that organisations must address to ensure successful implementation. From data-related issues to human factors and ethical concerns, these barriers must be thoughtfully managed.

Data Quality and Integration Challenges

One of the most significant hurdles in deploying AI across supply chains is ensuring high-quality, integrated data. AI systems rely heavily on accurate, consistent, and real-time data to deliver meaningful insights. However, many businesses struggle with fragmented data across legacy systems, inconsistent formats, or incomplete records. Without a unified data infrastructure, the effectiveness of AI models is greatly diminished. Businesses must invest in robust data governance and integration frameworks to ensure seamless operation of AI tools across the supply chain.

Change Management and Workforce Adaptation

Implementing a supply chain with AI often demands significant organisational change. Employees may resist new technologies due to fear of redundancy or unfamiliarity with AI systems. Successful integration requires comprehensive change management strategies, including clear communication, staff training, and up skilling programmes. Empowering employees with the necessary knowledge and tools ensures a smoother transition and fosters collaboration between human expertise and machine intelligence.

Ethical and Security Concerns in AI-Driven Supply Chains

With the increasing reliance on AI, ethical and security issues become paramount. AI algorithms must be designed to avoid bias, particularly in decision-making processes that affect procurement, supplier selection, or distribution. Moreover, supply chains handle vast amounts of sensitive data, making them a target for cyber-attacks. Organisations must prioritise cybersecurity measures and ethical AI practices, including transparency, accountability, and compliance with data protection regulations.

In conclusion, while the advantages of integrating supply chain with AI are substantial, businesses must be prepared to tackle the associated challenges. Addressing data quality, managing workforce change, and upholding ethical standards are essential steps in unlocking the full potential of AI in supply chain operations. By navigating these obstacles strategically, organisations can build smarter, more resilient supply chains.

How does LAI Support Learning Artificial Intelligence and Its Applications in Supply Chain?

The integration of supply chain with AI is rapidly transforming global logistics, inventory management, and demand forecasting. To keep pace with these innovations, LAI offers comprehensive educational programmes designed to equip professionals with the knowledge and practical skills needed to thrive in this AI-driven landscape.

Specialised Courses on AI in Supply Chain and Logistics

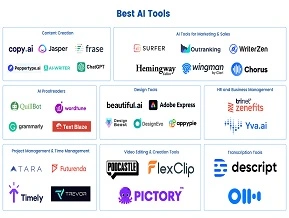

LAI provides a variety of tailored courses that focus specifically on the intersection of artificial intelligence and supply chain management. These programmes cover foundational concepts such as AI algorithms, data analytics, and machine learning, alongside specialised modules that explore real-world applications in logistics, procurement, and warehouse automation. Learners gain an in-depth understanding of how AI is being used to improve efficiency, accuracy, and decision-making in supply chain operations.

Practical Training on AI Tools for Inventory and Demand Optimisation

In addition to theoretical knowledge, LAI’s courses emphasise hands-on training using current AI technologies and tools. Learners are introduced to platforms that enable predictive analytics, real-time inventory tracking, and automated demand forecasting. Through interactive case studies, simulations, and project work, students develop practical experience in applying AI to streamline inventory control and optimise demand planning — key pillars in the effective use of supply chain with AI.

Preparing Supply Chain Professionals for an AI-Powered Future

As the industry shifts toward digital and AI-powered ecosystems, LAI’s programmes are strategically designed to future-proof careers. The courses are suitable for supply chain professionals at all levels — from entry-level workers seeking foundational knowledge to experienced managers looking to implement AI strategies in their organisations. By focusing on both strategic insights and practical capabilities, LAI prepares learners to lead AI adoption, enhance supply chain resilience, and drive innovation within their roles.

In summary, LAI plays a vital role in bridging the skills gap in the era of supply chain with AI, ensuring professionals are well-equipped to meet the demands of a rapidly evolving industry.

Conclusion

Artificial intelligence and supply chain integration has revolutionised the way businesses handle inventory and forecast demand. By harnessing the power of AI to analyse large datasets, identify patterns, and provide real-time insights, companies are now able to significantly enhance operational efficiency and reduce costs across various supply chain functions. As a result, supply chain with AI empowers organisations to respond rapidly to market fluctuations, minimise stock imbalances, and improve overall customer satisfaction. This cutting-edge technology enables better decision-making, reduces human error, and increases agility in today’s fast-paced business environment. To stay competitive and relevant, professionals must embrace these innovations and adapt to evolving industry demands. LAI offers specialised AI in supply chain courses designed to equip learners with practical skills and hands-on training. By enrolling, you’ll gain the expertise needed to lead digital transformation in your organisation and thrive in a future shaped by AI-driven supply chain strategies.