Artificial Intelligence and Manufacturing: How AI Is Cutting Costs and Boosting Efficiency?

Artificial intelligence and manufacturing involve the integration of AI technologies into manufacturing processes to improve automation, precision, and decision-making. By utilizing data-driven insights, machine learning, and robotics, this integration allows factories to operate more intelligently and efficiently. The role of Artificial Intelligence in Manufacturing is growing rapidly as industries implement smart systems for predictive maintenance, quality control, supply chain optimization, and production planning. These AI-powered solutions help manufacturers reduce errors, minimize downtime, and enhance overall productivity. Embracing AI is essential for companies looking to cut operational costs and increase efficiency. Through automating repetitive tasks, optimizing resource utilization, and providing real-time monitoring, AI leads to significant cost savings and faster production cycles. In today’s competitive landscape, adopting AI technologies is a critical factor for sustainable growth and ongoing innovation in the manufacturing sector.

Key Applications of Artificial Intelligence in Manufacturing

Predictive Maintenance and Equipment Monitoring

One of the most impactful applications of artificial intelligence and manufacturing is predictive maintenance. AI systems analyse data from sensors embedded in machinery to predict when equipment is likely to fail or require maintenance. This proactive approach helps prevent unexpected breakdowns, reduces downtime, and extends the lifespan of expensive manufacturing assets. By continuously monitoring equipment performance in real time, manufacturers can schedule maintenance only when necessary, saving both time and money compared to traditional scheduled maintenance methods.

Quality Control through AI-Powered Inspection Systems

AI-powered inspection systems have revolutionized quality control in manufacturing. Using computer vision and machine learning algorithms, these systems can detect defects and irregularities with greater accuracy and speed than human inspectors. They can identify minute flaws in products during production, ensuring only high-quality goods reach the market. This not only improves customer satisfaction but also reduces waste and rework costs. The integration of AI-driven quality control helps manufacturers maintain consistent standards and comply with regulatory requirements more effectively.

Supply Chain Optimization and Inventory Management

Another critical area where artificial intelligence and manufacturing intersect is supply chain optimization. AI algorithms analyse large volumes of data from suppliers, production schedules, and market demand to optimize inventory levels and reduce bottlenecks. This leads to better forecasting, reduced holding costs, and improved delivery times. AI can also identify potential disruptions in the supply chain and recommend alternative sourcing or logistics strategies. By streamlining supply chain operations, manufacturers can respond more swiftly to changing market conditions and improve overall efficiency.

In summary, AI’s integration into manufacturing processes—from predictive maintenance and quality control to supply chain management—is transforming the industry. These applications help businesses reduce costs, enhance product quality, and stay competitive in an increasingly automated and data-driven world.

How Does Artificial Intelligence in Manufacturing Cut Costs?

Reducing Downtime and Maintenance Expenses with AI Analytics

One of the key ways artificial intelligence and manufacturing combine to cut costs is through predictive analytics that reduce downtime. AI-powered systems monitor equipment health continuously, analysing data from sensors to predict failures before they occur. This allows manufacturers to perform maintenance only when necessary, avoiding costly unplanned breakdowns and production halts. By minimizing downtime, companies can maintain higher productivity levels and reduce expensive repair costs, ultimately improving their bottom line.

Minimizing Waste and Defects through Intelligent Automation

AI-driven automation plays a crucial role in reducing waste and product defects in manufacturing. Intelligent machines equipped with AI can perform precise and consistent operations, which decreases human errors and material waste. Additionally, AI-based quality control systems inspect products in real time, quickly identifying defects and allowing immediate correction. This reduces the number of defective products reaching customers and limits the need for costly rework or recalls. As a result, manufacturers can achieve significant savings in materials and improve overall product quality.

Streamlining Operations and Workforce Management

Artificial intelligence also helps streamline manufacturing operations and optimize workforce management. AI systems analyse production workflows, identify inefficiencies, and recommend improvements to increase operational speed and accuracy. Furthermore, AI-driven scheduling tools can allocate human resources more effectively, ensuring the right skills are deployed at the right times without overstaffing. This reduces labour costs and improves worker productivity. By automating routine tasks and supporting decision-making processes, AI enables manufacturers to operate more efficiently and cost-effectively.

In conclusion, artificial intelligence and manufacturing integration provides powerful tools to reduce costs by cutting downtime, minimizing waste, and optimizing both operations and workforce management. These innovations are essential for manufacturers seeking to stay competitive and improve profitability in today’s fast-paced industrial environment.

Boosting Efficiency with AI-Driven Manufacturing Processes

Enhancing Production Speed and Flexibility Using AI Robotics

The integration of artificial intelligence and manufacturing has led to the rise of AI-driven robotics that significantly enhance production speed and flexibility. These intelligent robots can perform complex tasks faster and with higher precision than traditional machinery. Unlike fixed automation, AI robotics adapt to different tasks and product variations without requiring extensive reprogramming. This flexibility enables manufacturers to quickly adjust production lines in response to new product designs or changing customer demands, reducing downtime and increasing overall throughput.

Real-Time Data Analysis for Faster Decision-Making

Another critical advantage of combining AI with manufacturing is the ability to perform real-time data analysis. AI systems collect and process vast amounts of data from sensors, machines, and supply chains instantly. This continuous flow of insights allows managers to make faster, data-driven decisions to optimize production schedules, detect anomalies, and respond to issues before they escalate. Real-time analytics also improve forecasting accuracy, helping companies anticipate demand fluctuations and plan resources more effectively.

Adaptive Manufacturing Systems That Respond to Demand Changes

Adaptive manufacturing systems powered by AI provide manufacturers with the ability to dynamically respond to market and demand changes. These systems use machine learning algorithms to analyse sales trends, inventory levels, and customer preferences. Based on this data, they automatically adjust production volumes and schedules to match current demand, reducing overproduction and inventory costs. By being more responsive and agile, manufacturers can improve customer satisfaction while maintaining cost efficiency.

In summary, the fusion of artificial intelligence and manufacturing enables smarter, faster, and more flexible production processes. AI-driven robotics enhance speed and adaptability, real-time data analysis supports quicker decision-making, and adaptive systems ensure production aligns closely with demand. Together, these innovations drive significant efficiency gains, helping manufacturers stay competitive in a rapidly evolving industrial landscape.

Challenges and Considerations When Implementing AI in Manufacturing

Integration with Existing Legacy Systems

One of the primary challenges in adopting artificial intelligence in manufacturing is integrating new AI technologies with existing legacy systems. Many manufacturing facilities operate with outdated hardware and software that were not designed to communicate with modern AI tools. This lack of compatibility can lead to costly upgrades, system downtime, or inefficient workflows. Successfully bridging this gap requires careful planning, selecting AI solutions that support interoperability, and sometimes redesigning parts of the production infrastructure to accommodate new technologies.

Data Security and Privacy in Manufacturing Environments

Implementing AI in manufacturing also raises important concerns about data security and privacy. Manufacturing processes generate large volumes of sensitive data, including proprietary designs, production metrics, and supplier information. As AI systems collect, store, and analyse this data, protecting it from cyber threats becomes critical. Manufacturers must establish robust cybersecurity protocols, encrypt sensitive data, and comply with relevant regulations to ensure that confidential information is not compromised. Failure to address these security issues can lead to financial losses, reputational damage, and legal consequences.

Training Workforce for AI-Enhanced Roles

The transition to AI-powered manufacturing also necessitates significant workforce training and development. Employees need new skills to manage, operate, and maintain AI-driven systems. This includes understanding data analytics, machine learning concepts, and troubleshooting AI technologies. Organizations must invest in up skilling their workforce through training programs and continuous education. Additionally, managing change is vital, as some workers may feel uncertain about their roles or fear job displacement. A thoughtful approach to workforce transition can help maximize the benefits of AI while fostering employee engagement and acceptance.

In conclusion, while the benefits of artificial intelligence in manufacturing are significant, companies must carefully address integration with legacy systems, data security challenges, and workforce training needs. By overcoming these obstacles, manufacturers can successfully harness AI to drive innovation, efficiency, and competitive advantage in the evolving industrial landscape.

Future Trends in Artificial Intelligence and Manufacturing

Emerging AI Technologies Shaping Manufacturing Innovation

The future of artificial intelligence in manufacturing is being driven by several cutting-edge technologies that promise to reshape the industry. Among these, advanced machine learning algorithms, edge computing, and digital twins stand out. Machine learning continues to improve predictive capabilities, enabling smarter maintenance and quality control. Edge computing allows real-time data processing directly on the factory floor, reducing latency and improving response times. Digital twins—virtual replicas of physical manufacturing systems—offer unprecedented insights by simulating processes and predicting outcomes before actual implementation. These innovations collectively enhance precision, reduce costs, and increase operational agility.

The Role of AI in Sustainable and Smart Manufacturing

Sustainability is becoming a top priority across manufacturing sectors, and AI is at the forefront of this shift. By optimizing resource usage, reducing waste, and minimizing energy consumption, AI-powered systems contribute to greener production practices. Smart manufacturing incorporates AI to monitor environmental impacts in real-time and adjust processes dynamically to meet sustainability goals. Additionally, AI facilitates circular economy models by improving product lifecycle management and enabling efficient recycling. The integration of AI in sustainable manufacturing not only supports environmental responsibility but also drives long-term profitability.

Predictions for AI’s Impact on Global Manufacturing Markets

Looking ahead, artificial intelligence in manufacturing is expected to significantly influence global markets by enhancing competitiveness and fostering innovation. AI-driven automation will streamline supply chains and enable mass customization, meeting increasingly diverse consumer demands. Countries and companies that adopt AI early are likely to gain market share through higher productivity and improved product quality. However, this rapid technological evolution may also reshape the workforce, creating demand for new skill sets and encouraging collaboration between humans and machines. Overall, AI’s expanding role will transform manufacturing into a more connected, efficient, and sustainable industry worldwide.

In summary, the future trends in artificial intelligence in manufacturing highlight exciting advancements in technology, sustainability, and global market dynamics. Embracing these trends will be key for manufacturers aiming to thrive in an increasingly competitive and environmentally conscious world.

How can LAI Help You Master Artificial Intelligence in Manufacturing?

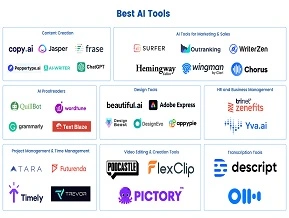

Comprehensive AI Courses Tailored for Manufacturing

At LAI, we offer specialized courses designed to help you master artificial intelligence in manufacturing. Our curriculum focuses on the practical applications of AI technologies within industrial environments, covering topics such as machine learning, predictive maintenance, robotics, and smart automation. Whether you’re a beginner or an experienced professional, LAI’s courses provide a strong foundation in AI concepts while emphasizing how they can be leveraged to optimize manufacturing processes. With expert instructors and up-to-date content, you’ll gain a clear understanding of how AI is transforming the manufacturing landscape.

Hands-On Practical Training for Real-World Implementation

LAI emphasizes experiential learning by providing hands-on training opportunities that prepare you to deploy AI tools effectively in real manufacturing settings. Through case studies, simulations, and lab exercises, you will practice using AI-driven software and hardware solutions to solve real industrial challenges such as quality control, supply chain optimization, and equipment monitoring. This practical experience ensures that you not only learn theoretical concepts but also develop the skills needed to implement AI systems that enhance efficiency, reduce costs, and improve product quality.

Preparing Professionals for the Future of AI-Driven Manufacturing

As artificial intelligence in manufacturing continues to evolve, the demand for skilled professionals who understand both AI technology and industrial operations is rapidly increasing. LAI’s training programs are designed to prepare you for this future by equipping you with the knowledge and competencies needed to succeed in an AI-driven manufacturing world. Beyond technical skills, our courses also cover change management and the integration of AI with existing systems, ensuring you are ready to lead or contribute to digital transformation initiatives. By joining LAI, you position yourself at the forefront of manufacturing innovation and open doors to exciting career opportunities.

In summary, LAI’s focused courses, practical training, and forward-looking curriculum make it the ideal place to master artificial intelligence in manufacturing and become a valuable asset in the evolving industrial sector.

Conclusion

Artificial intelligence and manufacturing have combined to create powerful solutions that significantly cut costs and boost operational efficiency. From reducing downtime through predictive maintenance to streamlining production with adaptive systems, AI technologies are transforming the way manufacturers operate. These advancements not only improve productivity but also enhance product quality and reduce waste, making manufacturing processes more sustainable and competitive. To maintain a competitive edge in today’s rapidly evolving industrial landscape, it is essential for manufacturers and professionals to adopt artificial intelligence in manufacturing. Leveraging AI-driven tools and insights allows companies to innovate continuously, respond faster to market demands, and optimize resources effectively. Take the next step in your career by exploring LAI’s specialized courses on AI and manufacturing. These programs provide the knowledge and practical skills necessary to harness AI’s full potential, helping you lead the future of smart manufacturing. Start your journey with LAI today and unlock new opportunities in this dynamic field.