Why AI in Supply Chain is a Must-Have Strategy for Modern Businesses?

What is Understanding AI in Supply Chain?

AI in Supply Chain is transforming the way businesses manage operations, optimize logistics, and respond to market demand. By integrating advanced technologies such as machine learning and predictive analytics, companies can enhance visibility, reduce costs, and make smarter, faster decisions throughout the supply chain.

Defining Artificial Intelligence in the Supply Chain Context

In a supply chain context, artificial intelligence refers to the use of computer systems that can simulate human intelligence to perform tasks such as learning from data, recognizing patterns, and making predictions. These AI systems can adapt over time and improve performance without explicit programming—making them ideal for complex, data-heavy environments like global supply chains.

Key AI Technologies Used

Several technologies drive the integration of supply chain and AI:

- Machine Learning helps identify trends and anomalies in massive datasets.

- Predictive Analytics enables forecasting of demand, supply disruptions, or maintenance needs.

- Computer Vision is used in warehouses for inventory tracking and quality inspection.

- Natural Language Processing (NLP) supports automation in communication, such as supplier emails or customer queries.

Together, these tools offer a smarter, more resilient supply chain infrastructure.

Real-World Applications in Sourcing, Logistics, and Demand Forecasting

AI is actively used in real-world supply chain operations. For example:

- In sourcing, AI can evaluate suppliers, predict lead times, and assess risks.

- In logistics, route optimization algorithms reduce delivery times and fuel costs.

- In demand forecasting, AI models predict buying trends based on historical and real-time data, helping to prevent overstocking or stockouts.

The adoption of AI in supply chain management is no longer optional for businesses aiming to stay competitive. As the technology matures, its impact will only grow stronger, reshaping supply chains to be more agile, efficient, and data-driven.

Why Supply Chain and AI are the Perfect Match?

AI in Supply Chain is proving to be a game-changer by offering powerful tools to handle complexity, improve efficiency, and boost resilience. As supply chains become more global and data-driven, artificial intelligence offers the speed and intelligence needed to keep operations agile and competitive.

AI’s Ability to Analyse Vast Data and Predict Outcomes

Modern supply chains generate massive volumes of data from inventory systems, logistics networks, sensors, and customer interactions. AI can process and analyse this data in real-time, uncovering hidden patterns and generating actionable insights. This capability allows companies to forecast demand, predict disruptions, and optimize inventory levels more accurately than ever before.

Enhancing Decision-Making and Reducing Human Error

One of the most valuable benefits of supply chain and AI integration is enhanced decision-making. AI algorithms support data-backed decisions, reducing reliance on guesswork and minimizing human errors. For example, AI can suggest the most cost-effective supplier or recommend the optimal shipping route based on live traffic and weather data.

By removing manual errors and improving accuracy, AI increases reliability and reduces operational risk—key priorities for any supply chain leader.

Examples of Synergy: Smart Warehouses, Autonomous Deliveries, and Predictive Maintenance

The synergy between AI and supply chain processes is already visible across industries:

- Smart warehouses use AI for robotic automation, real-time inventory tracking, and order accuracy.

- Autonomous delivery vehicles and drones powered by AI are streamlining last-mile delivery, cutting costs and delays.

- Predictive maintenance uses AI to monitor machinery performance, preventing costly downtime and unexpected failures.

Together, these applications illustrate why supply chain and AI are a perfect match—not just in theory, but in practice. As the supply chain landscape grows more complex, AI will continue to be a driving force behind smarter, faster, and more resilient operations.

What are the Key Benefits of AI in Supply Chain for Modern Businesses?

AI in Supply Chain is no longer a futuristic concept—it's a current-day solution enabling businesses to transform operations, stay competitive, and build resilience. With the increasing complexity of global supply networks, AI offers a powerful toolkit to streamline processes and make smarter decisions.

Improved Efficiency and Cost Savings

AI automates time-consuming and repetitive tasks such as order processing, inventory management, and route optimization. Machine learning algorithms can identify inefficiencies in operations, helping businesses reduce waste, lower labour costs, and improve throughput. As a result, supply chain functions become faster and more cost-effective.

Enhanced Visibility and Transparency

Real-time data analysis powered by these improves end-to-end visibility. With predictive analytics, businesses can track shipments, monitor inventory levels, and anticipate delays. This transparency allows stakeholders to respond quickly to disruptions, improving overall coordination and customer satisfaction.

Better Risk Management and Demand Planning

AI enhances risk management by identifying early signs of potential disruptions, such as supplier issues or geopolitical events. It also supports demand forecasting by analysing historical data, seasonal trends, and market behaviour to produce accurate predictions. This helps companies plan production, manage inventory levels, and avoid stockouts or overstocking.

Sustainable and Eco-Friendly Operations

AI contributes to sustainability by optimizing energy usage, reducing emissions through smarter logistics, and minimizing waste in production and storage. By analysing supply chain activities, AI can suggest more eco-friendly transportation routes and promote the use of sustainable materials and practices.

In summary, the integration of AI in supply chain operations delivers measurable benefits across efficiency, transparency, risk mitigation, and sustainability. For modern businesses, adopting AI is not just a strategic advantage—it’s becoming a necessity in an increasingly dynamic and environmentally conscious world.

How Industry Leaders Use AI in Supply Chain?

It is not just a theoretical advantage—it’s a proven driver of performance for global industry leaders. Companies like Amazon, DHL, and Maersk are leading the charge by integrating AI into their supply chain operations, achieving tangible results and long-term value.

Amazon: Predictive Analytics and Smart Warehousing

Amazon is one of the most advanced users of AI in the supply chain. The company leverages AI-driven predictive analytics to forecast customer demand with remarkable accuracy. Its fulfilment centres use robotics and machine learning to manage inventory, sort packages, and reduce delivery times. AI also powers Amazon’s dynamic pricing and real-time shipping estimates, ensuring optimal customer experiences.

DHL: AI-Powered Logistics Optimization

DHL has adopted AI to improve logistics efficiency across its global network. Using AI algorithms, the company optimizes delivery routes, reduces fuel consumption, and predicts package delays. DHL’s AI-enabled warehouse robots handle sorting and packing tasks, increasing throughput and reducing labour costs. The result: faster deliveries and improved supply chain agility.

Maersk: Predictive Maintenance and Cargo Tracking

Global shipping giant Maersk uses AI in Supply Chain operations to monitor vessel performance and conduct predictive maintenance. By analysing sensor data in real time, AI helps detect potential equipment failures before they happen, minimizing downtime. Additionally, Maersk utilizes AI for cargo tracking and risk assessment, improving visibility and reducing delays.

Tangible ROI and Long-Term Gains

These industry leaders report measurable returns on their AI investments—ranging from cost savings and improved delivery times to higher customer satisfaction and more sustainable operations. As AI technology matures, the long-term gains continue to grow, setting a benchmark for others in the industry.

For companies aiming to modernize, these real-world examples underscore the value and necessity of embracing AI in the supply chain.

What are the Challenges and Considerations in Implementing AI in Supply Chain?

Supply Chain and AI offer transformative potential, but its implementation is not without challenges. Businesses must address technical, financial, and organizational hurdles to successfully integrate AI and maximize its value.

Data Quality and Integration Issues

AI systems rely on vast amounts of accurate, clean, and consistent data. In many supply chains, data is fragmented across departments, legacy systems, and external partners. Poor data quality or lack of integration can limit AI's effectiveness, leading to inaccurate predictions or flawed automation. Organizations must invest in proper data governance and build infrastructure capable of unifying and managing data across the entire supply chain.

High Initial Investment and Change Management

Implementing AI technologies often requires significant upfront investment—in software, hardware, and training. Additionally, AI adoption demands changes in workflows, processes, and company culture. Resistance from staff and a lack of clear leadership can stall implementation. To overcome these barriers, companies need a clear AI roadmap, stakeholder alignment, and a strong change management strategy.

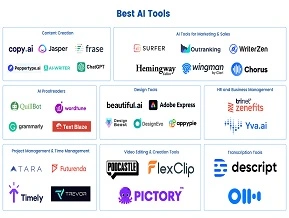

Skills Gap and the Need for AI Education

One of the most pressing challenges is the shortage of skilled professionals who understand both supply chain operations and artificial intelligence. This talent gap can slow down AI adoption and reduce its impact.

To address this, continuous learning and upskilling are critical. Platforms like LAI (Learn Artificial Intelligence) are playing a key role by offering specialized training for supply chain professionals. LAI’s mission is to bridge the gap between theory and practical application, enabling businesses to build internal AI capabilities effectively.

While challenges exist, they are surmountable. With the right strategy, investment, and education, businesses can overcome these obstacles and unlock the full potential of AI in supply chain operations.

What is the Role of AI in the Next-Gen Supply Chain?

AI in Supply Chain is rapidly evolving, and the future promises even greater innovation as emerging technologies converge. From real-time data analysis to autonomous decision-making, AI will be at the core of next-generation supply chains that are smarter, more agile, and highly adaptive.

Trends: AI + IoT, Digital Twins, Block chain Integration

The fusion of AI with other technologies is set to redefine supply chain capabilities. The combination of AI and the Internet of Things (IoT) allows real-time tracking of goods, predictive maintenance, and smarter inventory management. Digital twins—virtual replicas of physical supply chains—use AI to simulate scenarios, forecast outcomes, and optimize performance. Meanwhile, blockchain integration ensures transparency and traceability, with AI analysing blockchain data for fraud detection and compliance.

These synergies enhance visibility, accuracy, and trust across the supply chain ecosystem.

Shift toward Autonomous, Adaptive Supply Chains

The future supply chain will be increasingly autonomous, with AI making real-time decisions on procurement, routing, inventory, and labour allocation. Machine learning algorithms will continually adapt based on live data and market shifts, enabling supply chains to self-correct and improve over time. This level of automation reduces human intervention, speeds up responses, and lowers operational risks.

The Increasing Importance of Agility and Resilience

In an era marked by global disruptions, agility and resilience are becoming strategic priorities. It supports proactive risk management, allowing businesses to anticipate disruptions and reroute or adjust operations quickly. Whether it’s responding to a supplier shutdown or a surge in demand, AI-driven systems ensure businesses stay ahead of uncertainty.

As we move toward 2030, AI will be the backbone of a more intelligent, efficient, and resilient global supply chain.

Why Learning AI for Supply Chain Professionals Is No Longer Optional?

AI in Supply Chain is reshaping the landscape of supply chain management, creating a strong demand for professionals who understand how to leverage AI technologies effectively. As organizations increasingly rely on AI-driven tools, being AI-literate has become essential for supply chain managers seeking to remain competitive and relevant.

The Rise in Demand for AI-Literate Supply Chain Managers

The rapid adoption of AI technologies across sourcing, logistics, and inventory management means that companies are looking for professionals who can interpret AI-generated insights and make informed decisions. Supply chain roles are evolving from manual and routine tasks to more strategic, data-driven responsibilities. This shift is driving a surge in demand for individuals skilled in AI concepts, analytics, and technology application.

How Upskilling with AI Opens New Career Opportunities

Upskilling in AI not only future-proofs careers but also opens doors to exciting new roles such as AI project manager, data analyst, and supply chain strategist. Professionals who can bridge the gap between technology and operations will become key drivers of innovation and efficiency within their organizations. Moreover, AI skills enhance problem-solving abilities and enable supply chain professionals to tackle complex challenges with confidence.

How LAI’s AI Courses Can Bridge the Skills Gap

Recognizing the urgent need for AI education, platforms like LAI (Learn Artificial Intelligence) offer tailored courses designed specifically for supply chain professionals. LAI’s programs cover essential AI tools and techniques, providing practical knowledge that can be immediately applied in real-world supply chain scenarios. By enrolling in these courses, professionals can close the skills gap, advance their careers, and contribute more effectively to their companies’ AI-driven transformations.

In today’s fast-evolving supply chain environment, learning AI is no longer optional—it’s a critical step toward success.

Conclusion

AI in Supply Chain offers significant benefits, including improved efficiency, enhanced visibility, and better risk management, all of which contribute to sustainable business success. Embracing AI is no longer a choice but a strategic imperative for companies seeking to thrive in an increasingly complex and dynamic market. For supply chain professionals and organizations alike, developing AI skills is essential to unlock these advantages and future-proof operations. Start your AI learning journey today with LAI (Learn Artificial Intelligence) and position yourself at the forefront of innovation and resilience in supply chain management.