AI and Supply Chain: How Artificial Intelligence is Revolutionizing Logistics in 2025?

What is the Definition and Evolution of Supply Chain in AI?

The concept of supply chain in AI refers to the integration of artificial intelligence technologies into the management and optimization of supply chain processes. This intersection brings together advanced AI methods such as machine learning (ML), natural language processing (NLP), and computer vision to transform traditional logistics operations into intelligent, data-driven systems. By automating decision-making and improving predictive accuracy, AI is reshaping the way goods are produced, transported, and delivered.

The adoption of AI within supply chains marks a fundamental shift from traditional, manual processes to intelligent automation that leverages vast amounts of data. This evolution is driven by the increasing complexity of global supply networks, which require faster, more accurate decision-making to maintain competitiveness. As AI technologies continue to mature, they enable supply chains to become more predictive, adaptive, and efficient—helping companies respond proactively to disruptions, optimize resource allocation, and enhance customer satisfaction. Understanding this evolution is essential for businesses aiming to harness the full power of AI and stay ahead in today’s fast-paced logistics landscape.

The Intersection of AI Technologies and Logistics

At the core of the supply chain are several key technologies. Machine learning algorithms analyse historical data to forecast demand and optimize inventory levels, reducing waste and improving service quality. Natural language processing powers automated communication systems, enabling smoother interactions between suppliers, customers, and logistics platforms. Computer vision technology enhances warehouse operations by facilitating real-time visual inspection, quality control, and inventory tracking. Together, these AI components create a smarter, more responsive supply chain that can adapt to changing conditions with minimal human intervention.

Historical Development and Milestones

The evolution of AI in supply chain management has been gradual but impactful. Early automation efforts focused on basic data processing and rule-based systems. However, advancements in computational power and big data analytics in the 2010s accelerated AI adoption. Milestones include the deployment of predictive analytics for demand planning, the rise of autonomous warehouse robots, and the integration of AI-driven transportation management systems. Today, AI is no longer a futuristic concept but a critical element powering supply chain resilience and agility in an increasingly complex global market.

What are the Benefits of AI and Supply Chain Integration?

The integration of ai and supply chain systems is fundamentally transforming the way businesses manage their logistics and overall operations. By embedding advanced AI technologies into various supply chain processes such as inventory management, demand forecasting, and transportation planning companies can unlock a wide range of benefits. These benefits include enhanced operational efficiency, significant cost reductions, and improved accuracy in decision-making. Furthermore, AI-powered supply chains enable businesses to deliver better customer experiences by ensuring faster, more reliable deliveries and greater transparency throughout the logistics network. As supply chains become more dynamic and complex, the role of AI becomes increasingly critical in maintaining competitiveness and driving continuous innovation.

Real-Time Visibility and Smarter Decision-Making

One of the most significant advantages of AI integration in supply chains is real-time visibility across all stages—from procurement and production to distribution and delivery. AI-powered systems collect and analyse vast amounts of data, providing up-to-date insights into inventory levels, shipment statuses, and supplier performance. This visibility enables faster and smarter decision-making, allowing businesses to react swiftly to disruptions or unexpected demand changes. Instead of relying on manual reporting or delayed information, supply chain managers can now make data-driven decisions that optimize workflows and reduce risks.

Predictive Analytics and Demand Forecasting

Predictive analytics is another critical benefit of combining AI and supply chain operations. Machine learning models analyse historical sales data, market trends, and external factors like weather or geopolitical events to forecast future demand accurately. This capability helps companies avoid overstocking or stock outs, streamline production schedules, and improve resource allocation. Accurate demand forecasting also reduces waste and lowers operational costs, contributing to more sustainable supply chain management.

What are the Top Use Cases of Supply Chain in AI in 2025?

The landscape of logistics and supply chain management is undergoing a rapid and profound transformation, largely fuelled by continuous advancements in artificial intelligence technologies. As we move through 2025, several key applications of supply chain in AI have emerged at the forefront of this evolution, reshaping how companies plan their operations, manage day-to-day activities, and optimize their entire logistics networks. These AI-driven innovations are enabling businesses to achieve unprecedented levels of efficiency, accuracy, and responsiveness. By harnessing AI, companies can better anticipate market demands, streamline inventory management, automate warehouse processes, and enhance overall supply chain visibility. This on-going revolution is not only improving operational performance but also helping businesses build resilience against disruptions and meet the ever-growing expectations of customers in today’s fast-paced market.

AI-Powered Demand and Supply Planning

One of the most impactful use cases is AI-driven demand and supply planning. Machine learning algorithms analyse vast amounts of historical data, market trends, and external factors such as weather or geopolitical events to create highly accurate forecasts. This predictive capability allows companies to better align inventory levels with actual demand, minimizing the risks of overstocking or stock outs. AI also optimizes supply planning by identifying potential bottlenecks and suggesting alternative sourcing or distribution strategies, helping businesses maintain smooth operations even amid uncertainty.

Smart Warehouse Automation with Robotics and Sensors

Another significant use case is the automation of warehouses through robotics and IoT sensors. AI-powered robots can handle repetitive tasks such as picking, packing, and sorting goods, significantly increasing speed and reducing human error. Sensors connected to AI systems provide real-time data on inventory levels, equipment status, and environmental conditions. This enables smarter warehouse management, where resources are allocated efficiently and potential issues are detected before they cause delays. The integration of robotics and sensors creates a highly responsive, flexible warehouse environment that adapts to fluctuating demands and operational needs.

What are the Key Technologies Powering AI and Supply Chain Innovations?

Artificial intelligence is fundamentally reshaping supply chain management by seamlessly integrating several advanced technologies designed to enhance forecasting accuracy, streamline automation, and improve overall decision-making processes. As supply chains become increasingly complex, the demand for intelligent systems that can analyse vast amounts of data and provide actionable insights is greater than ever. In 2025, key AI technologies such as machine learning and natural language processing (NLP) are at the forefront of this transformation. Machine learning algorithms help detect patterns and predict future trends, allowing companies to optimize inventory, reduce waste, and anticipate disruptions.

Machine Learning for Forecasting and Pattern Detection

Machine learning (ML) is at the heart of many AI and supply chain innovations. It enables systems to learn from historical data, identify patterns, and make accurate predictions without explicit programming. In supply chain management, ML is widely used for demand forecasting—helping companies anticipate customer needs and optimize inventory levels. Additionally, it detects anomalies such as supply disruptions or quality issues early, allowing businesses to take proactive measures. By continuously analysing real-time data, machine learning models improve over time, leading to more reliable and agile supply chain operations.

Natural Language Processing (NLP) for Automation

Natural language processing plays a crucial role in automating communication and information processing within the supply chain. NLP enables machines to understand and interpret human language, allowing for automated customer service interactions, processing of shipping documents, and seamless communication between suppliers and logistics partners. This reduces manual workload, speeds up processes, and minimizes errors caused by miscommunication. With NLP, companies can also analyse large volumes of unstructured data—such as emails and social media—to gain insights that improve supply chain strategies.

What are the Challenges in Implementing Supply Chain in AI Solutions?

Implementing AI solutions in supply chain management offers significant opportunities to enhance efficiency, reduce costs, and improve overall operational performance. However, this transformation also comes with several challenges that organizations must carefully navigate. These hurdles include technical, organizational, and data-related complexities that can impede the successful deployment of AI technologies. To fully harness the benefits of supply chain in AI, businesses need to address issues such as data quality, infrastructure readiness, and seamless integration with existing legacy systems.

Data Quality and Infrastructure Readiness

One of the biggest challenges in adopting AI for supply chains is ensuring the availability of high-quality, accurate data. AI models depend heavily on clean and comprehensive datasets to generate reliable insights. However, many organizations struggle with fragmented data sources, inconsistent formats, and incomplete records. Without proper data governance and infrastructure, AI solutions may produce flawed predictions or recommendations. Moreover, the existing IT infrastructure in many companies may lack the necessary processing power and storage capacity to support advanced AI workloads, requiring significant upgrades and investments.

Integration with Legacy Systems

Another major obstacle is integrating AI solutions with existing legacy systems that were not designed for modern, data-driven operations. Supply chains often rely on multiple, disparate platforms for inventory management, order processing, and transportation logistics. Bridging these systems with AI tools can be complex and costly, requiring customized interfaces and middleware. Furthermore, legacy systems may lack the real-time data capabilities needed for AI to function optimally, limiting the potential improvements in responsiveness and automation.

What are the Future of AI and Supply Chain Beyond 2025?

The future of AI and supply chain management promises to be truly transformative, fuelled by rapid advancements in technology that will fundamentally redefine how logistics and operations are planned, executed, and optimized. As we move beyond 2025, emerging innovations such as autonomous systems, advanced machine learning models, and secure data-sharing frameworks are expected to create supply networks that are not only smarter but also more adaptive and self-sufficient. These next-generation supply chains will be capable of responding dynamically to shifting market demands, unexpected disruptions, and complex global challenges with greater speed and precision than ever before.

Autonomous Supply Chains and Self-Healing Networks

One of the most exciting prospects is the rise of autonomous supply chains powered by AI. These systems will leverage real-time data, machine learning, and advanced robotics to operate with minimal human intervention. Self-healing networks will automatically detect disruptions—such as delays, equipment failures, or supply shortages—and implement corrective actions without manual input. This level of automation will improve efficiency, reduce downtime, and enhance overall supply chain resilience.

AI and Blockchain Convergence for Transparency and Security

Another significant development will be the convergence of AI with blockchain technology. Blockchain’s decentralized ledger offers unparalleled transparency and traceability across supply chains, while AI enhances data analysis and predictive capabilities. Together, they will enable secure, tamper-proof tracking of goods and transactions, reducing fraud and ensuring compliance with regulations. This integration will foster trust among stakeholders, from manufacturers to end consumers, by providing verified, real-time information about product origins, handling, and delivery status.

How to Start Learning About Supply Chain in AI?

As the integration of AI in supply chain management continues to accelerate, professionals who want to stay competitive and relevant in the industry must actively acquire the necessary skills and knowledge. Supply chain is a rapidly evolving field that blends traditional logistics expertise with cutting-edge artificial intelligence technologies such as machine learning, predictive analytics, and automation. This fusion not only transforms how supply chains operate but also opens up exciting new career opportunities across various sectors. By mastering AI-driven tools and techniques, supply chain professionals can play a crucial role in driving efficiency, reducing costs, and enhancing customer satisfaction in increasingly complex and dynamic global logistics networks.

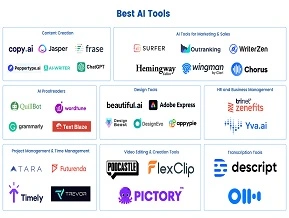

Recommended AI Skills and Tools for Logistics Professionals

To get started, logistics professionals should focus on building foundational AI skills such as machine learning, data analytics, and automation techniques. Familiarity with programming languages like Python and tools such as TensorFlow or PyTorch can be highly beneficial. Additionally, understanding specific AI applications in supply chains—such as predictive analytics for demand forecasting, robotic process automation for warehouse management, and natural language processing for automated communication—is critical.

Overview of Online Courses and Resources

Fortunately, there are many online resources available for those interested in learning about supply chain. Platforms like Coursera, Udacity, and edX offer specialized courses covering AI fundamentals as well as supply chain management principles. For learners seeking tailored content, the LAI (Learn Artificial Intelligence) website provides comprehensive courses focused on AI’s role in logistics and supply chain optimization. These courses include practical examples, case studies, and hands-on projects that help bridge theory with real-world applications.

Conclusion

AI and supply chain technologies are fundamentally transforming the logistics landscape, enabling smarter, faster, and more efficient operations. The integration of artificial intelligence into supply chain management is no longer optional but a strategic necessity for businesses aiming to stay competitive in today’s fast-paced market. Professionals who understand the supply chain in AI will be better equipped to drive innovation and optimize processes. To thrive in this evolving environment, embracing AI learning is essential. Start building your AI skills now to lead the future of logistics and supply chain management confidently.